Preventing Short-Circuit Fires: Why They Happen and How to Stop Them Before Ignition

Short-circuit fires are among the fastest and most destructive electrical fire incidents. Unlike overheating or overload fires that develop slowly, a short circuit can trigger instant ignition, violent sparks, molten metal, and explosive fire spread within seconds.

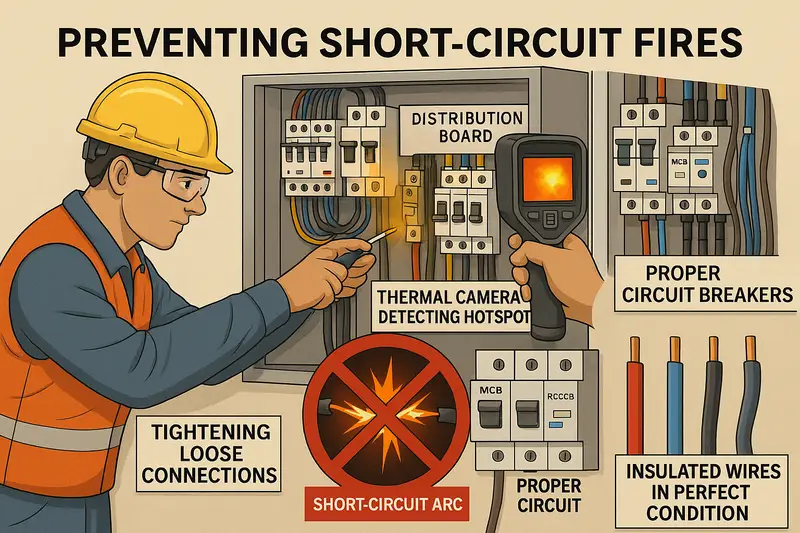

According to HSE electrical safety guidance, short-circuit fires can be prevented through proper circuit protection, sound insulation, effective earthing, and regular inspection and maintenance.

Most short-circuit fires are not accidents. They are the result of predictable conditions such as damaged insulation, loose wiring, moisture, or poor-quality components. Understanding how short circuits form and how to prevent them is one of the most effective ways to reduce electrical fire risk in homes, commercial buildings, and industrial facilities.

What Is a Short Circuit in Simple Terms

A short circuit occurs when electricity takes an unintended low-resistance path instead of flowing through the designed load. This allows a massive amount of current to flow instantly.

In practical terms, a short circuit happens when:

- Live and neutral wires touch

- Live wire contacts earth or metal body

- Two live phases come into contact

- Moisture or conductive debris bridges terminals

The result is an immediate surge of current far beyond safe limits.

Why Short Circuits Cause Fires So Quickly

Short circuits are dangerous because they combine three fire triggers at once:

- Extremely high current

- Intense heat

- Electrical arcing

When a short circuit occurs:

- Current can rise dozens of times above normal

- Arcs form with temperatures hotter than molten steel

- Insulation, dust, and nearby materials ignite instantly

If protection devices fail or react too slowly, a fire starts before anyone can respond.

The Most Common Causes of Short-Circuit Fires

Damaged Cable Insulation

Insulation failure is the most frequent cause of short circuits.

Insulation can be damaged by:

- Aging and brittleness

- Overheating due to overload

- Mechanical stress

- Rodents chewing cables

- Chemical vapors

- Poor installation practices

Once conductors are exposed, even a small movement can cause contact and ignition.

Loose Electrical Connections

Loose terminals are silent fire starters.

When a connection loosens:

- Resistance increases

- Heat builds up at the joint

- Insulation carbonizes

- Arcing begins under load

Over time, this leads directly to short circuits inside panels, sockets, and equipment.

Moisture and Water Ingress

Water reduces insulation resistance and creates unintended conductive paths.

High-risk locations include:

- Bathrooms and kitchens

- Basements

- Outdoor sockets

- Pump rooms

- Industrial wash areas

Moisture-related short circuits often occur suddenly after rain, cleaning, or flooding.

Overloading and Heat Damage

Continuous overloading weakens insulation over time.

As insulation degrades:

- Conductors move closer

- Insulation melts or cracks

- Short circuits occur under normal operating conditions

This is why overloaded circuits often fail months after installation.

Rodent Damage

Rodents frequently chew cable insulation, especially in concealed spaces.

Once copper is exposed:

- Small vibrations cause contact

- Arcing occurs

- Fires start inside walls or ceilings

Rodent damage is a major cause of night-time electrical fires.

Poor-Quality or Counterfeit Electrical Components

Low-quality switches, sockets, cables, and breakers fail faster and unpredictably.

Common problems include:

- Undersized conductors

- Poor insulation

- Weak contact pressure

- Breakers that fail to trip during faults

When protection devices fail, short circuits turn into fires.

Why Protection Devices Matter So Much

Short-circuit fires usually occur only when protection fails.

Proper protective devices are designed to:

- Detect abnormal current instantly

- Disconnect power before ignition

- Limit arc energy

Key protective devices include:

- Circuit breakers for overload and short circuit

- Earth leakage protection for insulation faults

- Arc fault protection for loose or damaged wiring

- High-rupturing-capacity fuses for high-energy systems

When these devices are missing, oversized, damaged, or counterfeit, fire risk increases dramatically.

Installation Practices That Prevent Short Circuits

Good installation prevents most short-circuit fires.

Critical practices include:

- Correct cable sizing for load

- Proper tightening of terminals

- Use of lugs and ferrules

- Avoiding cable joints where possible

- Proper routing away from heat and moisture

- Adequate spacing inside panels

Many short circuits trace back to poor workmanship, not design flaws.

The Role of Maintenance in Preventing Short Circuits

Short circuits rarely occur in well-maintained systems.

Effective maintenance includes:

- Periodic tightening of connections

- Cleaning dust inside panels

- Checking for discoloration or burn marks

- Thermal scanning to detect hot spots

- Insulation resistance testing

- Inspecting cables for physical damage

Maintenance turns hidden faults into visible warnings.

Early Warning Signs of Short-Circuit Risk

Most short-circuit fires provide warning signs that are often ignored.

Common indicators include:

- Burning smell near sockets or panels

- Frequent breaker tripping

- Warm switches or outlets

- Flickering lights

- Buzzing or crackling sounds

- Discolored sockets or cables

These signs demand immediate inspection, not temporary fixes.

Preventing Short-Circuit Fires in Homes

Practical household measures include:

- Avoid overloading extension boards

- Replace damaged cords immediately

- Use quality sockets and switches

- Install earth leakage protection

- Keep electrical areas dry

- Avoid running cables under carpets

- Never bypass or oversize breakers

Most residential short-circuit fires are preventable with simple discipline.

Preventing Short-Circuit Fires in Commercial Buildings

Commercial environments should focus on:

- Dedicated circuits for heavy equipment

- Proper cable management

- Sealed panels to prevent dust and moisture

- Regular panel inspections

- Controlled access to electrical rooms

- Replacement of aging wiring

Electrical fires in offices often start after hours when no one is present.

Preventing Short-Circuit Fires in Industrial Facilities

Industrial systems carry higher fault energy and need stricter controls.

Effective strategies include:

- High-quality industrial-grade protection devices

- Thermographic inspections of MCC panels

- Vibration monitoring on machinery

- Rodent control programs

- Flameproof enclosures in hazardous areas

- Proper grounding and bonding

In industry, prevention is far cheaper than fire damage or shutdown.

What To Do If a Short Circuit Occurs

If a short circuit causes sparks, smoke, or fire:

- Switch off the main power supply immediately if safe

- Use only CO₂ or dry powder extinguishers

- Never use water on live electrical systems

- Evacuate if fire grows rapidly

- Call emergency services

Personal safety always comes before equipment.

Why Short-Circuit Fire Prevention Saves Lives

Short-circuit fires spread fast and produce toxic smoke.

They often occur:

- At night

- Inside walls

- In electrical rooms

- When buildings are unoccupied

Preventing them protects:

- Occupants

- Property

- Business continuity

- Critical infrastructure

Conclusion

Short-circuit fires are sudden, violent, and highly destructive, but they are also largely preventable. Most originate from damaged insulation, loose connections, moisture, overloading, or poor-quality components. When combined with failed or inadequate protection devices, these faults turn into instant fire events.

By using certified materials, following proper installation practices, performing regular inspections, maintaining protection devices, and responding quickly to warning signs, short-circuit fire risk can be reduced dramatically in homes, commercial buildings, and industrial facilities.

Electrical safety is not about reacting to fires, it is about eliminating the conditions that allow them to start.

Electrical Fire Safety: Causes, Controls, and Prevention Measures

Heat Sources in Industrial Fires: Causes, Risks, Control Measures and Prevention

Electrical Fire Causes: Detailed Explanation, Scientific Background, Risk Factors, and Prevention

Overloading and Overheating Risks: Causes, Safety Tips, Prevention