Fire Triangle Explained, Practical Fire Risk Control Guide for Workplaces

Fire incidents in workplaces rarely happen by accident. In most cases, they occur because one or more elements of the fire triangle were not properly controlled. After working on industrial shutdowns, electrical safety audits, and fire risk assessments, I have seen that understanding the fire triangle is not just theory. It is a practical tool used daily by safety professionals to prevent fires before they start.

This guide explains the fire triangle in a practical, inspection focused, and prevention oriented way, specifically for workplaces such as offices, factories, warehouses, and industrial sites.

What Is the Fire Triangle in Practical Terms

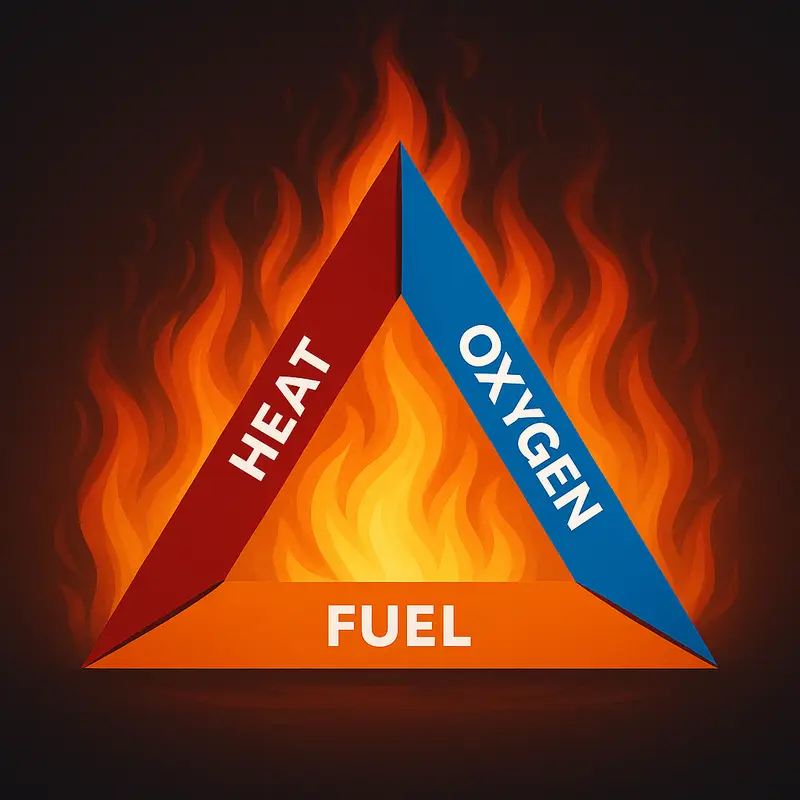

The fire triangle explains that three elements must be present at the same time for a fire to start and continue:

- Heat

- Fuel

- Oxygen

If any one of these elements is effectively controlled, a fire cannot occur.

In real workplaces, fire incidents usually happen not because all three were present intentionally, but because controls failed. Loose wiring, poor housekeeping, unsafe storage, or lack of supervision allow the triangle to form unintentionally.

According to HSE fire safety guidance, fire occurs when heat, fuel, and oxygen combine, which is the basic principle of the fire triangle.

Why the Fire Triangle Matters in Workplace Fire Safety

Understanding the fire triangle helps safety officers and employers to:

- Identify ignition sources during inspections

- Control combustible materials effectively

- Reduce fire load in work areas

- Select correct fire prevention measures

- Plan emergency response and firefighting actions

- Conduct meaningful fire risk assessments

Every fire risk assessment is essentially an evaluation of how well heat, fuel, and oxygen are being controlled.

Element 1: Heat, Common Workplace Ignition Sources

Heat is the trigger that initiates combustion. In workplaces, heat sources are often underestimated because many are hidden or develop slowly.

Common Heat Sources Found During Site Inspections

Electrical Sources

- Loose electrical terminations

- Overloaded power sockets

- Damaged cables and extension cords

- Overheated motors and panels

From site experience, electrical panel fires often start due to loose connections combined with dust accumulation. A minor spark can escalate rapidly if housekeeping is poor.

Mechanical and Friction Heat

- Overheated bearings

- Poorly lubricated machinery

- Conveyor belt friction

- Misaligned rotating equipment

Hot Work Activities

- Welding and gas cutting

- Grinding operations

- Use of gas torches

Hot Surfaces

- Boilers and furnaces

- Steam lines

- Engine exhaust systems

Practical Heat Control Measures

- Regular electrical thermography and inspections

- Proper machine lubrication schedules

- Hot work permit systems with fire watch

- Keeping combustibles away from hot surfaces

- Preventive maintenance programs

Controlling heat removes the first side of the fire triangle.

Element 2: Fuel, Managing Combustible Materials

Fuel is anything that can burn. In many workplaces, fuel accumulation is the most common failure point.

Common Fuel Sources in Workplaces

Solid Combustibles

- Paper and cardboard packaging

- Wooden pallets

- Plastic materials

- Insulation materials

- Waste and scrap

Flammable Liquids

- Diesel and petrol

- Solvents and thinners

- Oils and greases

- Cleaning chemicals

Gases

- LPG and propane

- Acetylene

- Natural gas

Combustible Dust

- Wood dust

- Flour dust

- Metal dust

Practical Fuel Control Measures

- Good housekeeping and waste removal

- Approved storage cabinets for flammable liquids

- Limiting quantities stored at workstations

- Proper gas cylinder storage and leak checks

- Dust extraction and cleaning systems

Fuel control is often the easiest and most effective fire prevention method.

Element 3: Oxygen, Often Overlooked but Dangerous

Oxygen supports combustion. Normal air contains about 21 percent oxygen, which is enough to sustain most fires.

Additional Oxygen Risks in Workplaces

- Oxygen cylinders used for cutting or medical purposes

- Oxidizing chemicals such as peroxides and nitrates

- Oxygen enriched environments

- Poorly ventilated confined spaces

Oxygen Control Measures

- Separating oxidizers from combustible materials

- Proper storage of oxygen cylinders

- Avoiding oil or grease contamination on oxygen equipment

- Using fire blankets, foam, or CO₂ to smother fires

- Closing doors and ventilation openings during fires

Reducing oxygen availability removes another side of the fire triangle.

Fire Tetrahedron and Why Some Fires Are Hard to Extinguish

Modern fire science adds a fourth element called the chemical chain reaction, forming the fire tetrahedron.

This explains why:

- Gas fires can reignite

- Certain fires continue even after heat is reduced

- Dry chemical powder is effective for flammable liquid and gas fires

Interrupting the chemical reaction is essential in many industrial fire scenarios.

How Fires Start on Real Sites, A Common Pattern

From practical site observations, most workplace fires follow this pattern:

- Poor housekeeping allows fuel to accumulate

- Minor heat source develops unnoticed

- Oxygen is freely available

- Ignition occurs suddenly

- Fire spreads rapidly due to fuel load

This pattern shows that fire prevention is far more effective than firefighting.

Fire Triangle Application in Fire Risk Assessment

During fire risk assessments, the fire triangle is used to:

- Identify ignition sources

- Identify combustible materials

- Assess ventilation and oxygen availability

- Evaluate likelihood of ignition

- Define control measures

A proper fire risk assessment always focuses on breaking at least one side of the fire triangle.

Fire Triangle Control Checklist for Workplaces

Use this checklist during inspections:

Heat Controls

- Electrical systems inspected and maintained

- Hot work controlled through permits

- Machinery properly lubricated

Fuel Controls

- Combustibles stored safely

- Waste removed regularly

- Flammable liquids limited and contained

Oxygen Controls

- Oxidizers stored separately

- Oxygen cylinders secured

- Fire doors and compartmentation maintained

Who Should Use This Guide

This guide is useful for:

- Safety officers and fire wardens

- Facility and maintenance managers

- Electrical and mechanical supervisors

- HSE professionals

- Employers responsible for workplace fire safety

Conclusion

The fire triangle is not just a theory taught in classrooms. It is a practical fire prevention tool used daily in workplaces. Fires start when heat, fuel, and oxygen come together due to failed controls. By systematically managing these three elements, workplaces can significantly reduce fire risks.

Effective fire safety is achieved not by reacting to fires, but by breaking the fire triangle before ignition occurs.

Heat Sources in Industrial Fires: Causes, Risks, Control Measures and Prevention