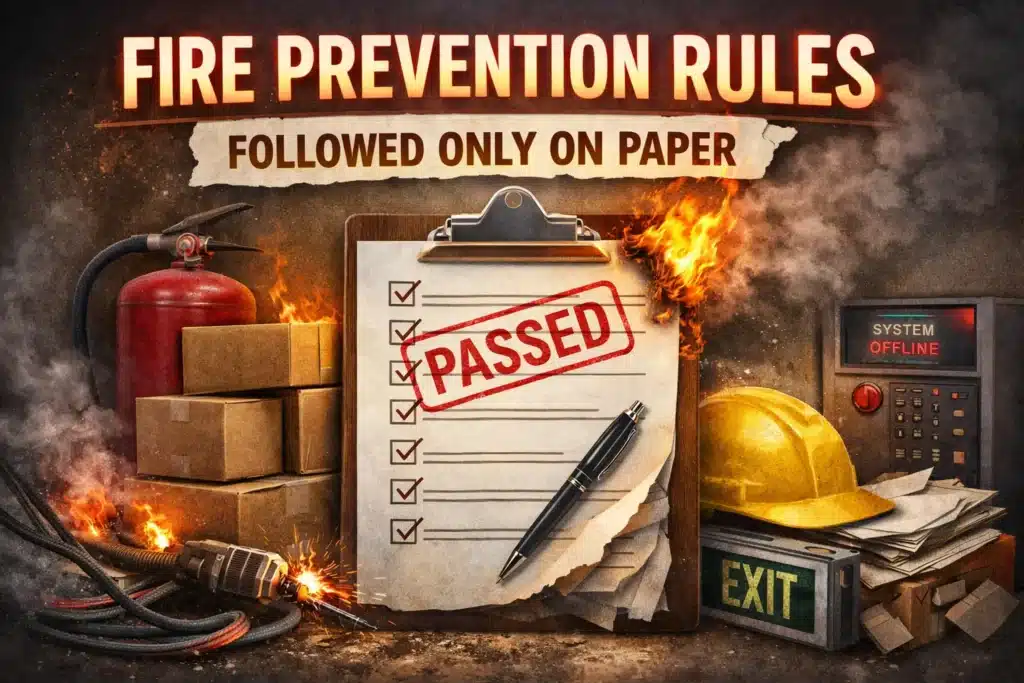

Fire Prevention Rules That Are Followed Only on Paper

Most workplaces proudly claim that fire prevention rules are implemented.

Policies exist. Procedures are documented. Checklists are signed.

Yet fire accidents continue to occur in facilities that appear fully compliant on paper.

This contradiction reveals a harsh reality.

Many fire prevention rules are followed only on paper, not in daily operations.

This article explains why paper compliance exists, which fire prevention rules are commonly ignored in practice, how this gap leads to accidents, and what organizations must do to move from paperwork to real fire prevention.

What Paper Compliance Really Means

Paper compliance occurs when:

• rules exist but are not practiced

• procedures are written but ignored

• checklists are filled without verification

• inspections are symbolic

• records do not reflect reality

Fire prevention becomes an administrative task instead of a safety culture.

Common Fire Prevention Rules Followed Only on Paper

1. Housekeeping Rules

Most fire prevention policies require:

• clean work areas

• removal of waste

• controlled storage of combustibles

In reality:

• waste accumulates behind machines

• packaging materials pile up

• flammable scrap is stored temporarily and forgotten

Housekeeping logs may be signed daily, but conditions tell a different story.

2. Electrical Safety Rules

Fire prevention rules usually mandate:

• regular electrical inspections

• proper cable management

• load control

However, actual conditions often include:

• temporary wiring

• overloaded sockets

• damaged cables in use

• unauthorized electrical modifications

Electrical checklists look perfect, while hazards remain energized.

3. Hot Work Permit Systems

On paper, hot work rules require:

• permits

• fire watch

• fire extinguishers

• area inspection

In practice:

• permits are issued after work starts

• fire watches are absent

• extinguishers are not checked

• permits are reused without inspection

The system exists, but control does not.

4. Storage and Segregation Rules

Fire prevention policies define:

• flammable storage limits

• segregation of chemicals

• safe distances from ignition sources

Reality often shows:

• mixed chemical storage

• flammables kept near heat sources

• excess stock stored temporarily and permanently

The rules are printed, not enforced.

5. Fire Extinguisher Accessibility Rules

Rules state that extinguishers must be:

• accessible

• visible

• unobstructed

Yet in many workplaces:

• extinguishers are blocked by materials

• access paths are ignored

• responsibility for checks is unclear

Inspection tags show compliance, accessibility does not.

6. Training and Awareness Rules

Fire prevention policies include:

• periodic training

• induction safety briefings

• mock drills

In practice:

• training is conducted only for records

• attendance is forced but engagement is low

• drills are announced and unrealistic

Workers know the rules exist, but not how to apply them.

Why Organizations Allow Paper-Only Fire Prevention

1. Compliance Is Easier Than Control

Maintaining documents is easier than enforcing behavior.

Paper compliance avoids conflict, cost, and operational disruption.

2. Safety Is Treated as a Department, Not a Responsibility

When fire prevention is seen as the safety officer’s job, ownership disappears from supervisors and workers.

3. Production Pressure Overrides Prevention

Fire prevention rules are ignored when they slow down work.

Shortcuts become normal, while rules remain theoretical.

4. Audits Reinforce Paper Culture

When audits focus on documents instead of field verification, organizations learn to prepare files instead of fixing risks.

How Paper Compliance Leads to Fire Accidents

Fire accidents often occur because:

• hazards existed but were normalized

• warning signs were ignored

• rules were assumed to be followed

• risks were hidden behind records

When a fire occurs, investigations reveal that rules existed but were never practiced.

Real-World Observation

In multiple industrial fire investigations, it is commonly observed that fire prevention rules were documented, approved, and audited, yet unsafe conditions were visible to anyone walking through the workplace.

The failure was not lack of rules, but lack of enforcement.

How to Convert Paper Rules Into Real Fire Prevention

Effective fire prevention requires:

• unannounced inspections

• field verification of compliance

• supervisor accountability

• behavior-based safety checks

• closure of repeated violations

• linking safety performance to management review

Rules must be seen, felt, and practiced daily.

According to guidance published by the National Fire Protection Association, effective fire prevention depends not only on written rules but on consistent implementation, supervision, and behavioral compliance at the workplace level. Fire safety programs that rely only on documented procedures without real-world enforcement often fail to prevent ignition and fire spread during actual emergencies.

Conclusion

Fire prevention rules do not fail because they are poorly written.

They fail because they are not lived.

A workplace that relies on paperwork instead of practice is not fire safe.

Real fire prevention exists only when rules are applied on the floor, not just stored in files.

Until organizations close the gap between what is written and what is done, fire accidents will continue to expose the truth behind paper compliance.

Why Fire Audits Fail to Prevent Accidents

Overconfidence That Leads to Workplace Fires

How Poor Housekeeping Leads to Fire Accidents

Frequently Asked Questions

1. Are fire prevention rules useless if followed only on paper?

Yes. Paper compliance creates false confidence and increases risk.

2. Why do audits fail to catch paper-only compliance?

Because audits often rely on documentation rather than现场 verification.

3. Who is responsible for enforcing fire prevention rules?

Management, supervisors, and workers, not only safety officers.

4. How can workers be encouraged to follow rules?

Through training, supervision, accountability, and leadership example.

5. What is the biggest danger of paper compliance?

It hides real hazards until a fire exposes them.