Electrical Fire Causes Explained: Why Most Electrical Fires Start Without Warning

Electrical fires rarely start with flames.

They usually begin silently inside walls, switchboards, cables, and equipment, long before anyone smells smoke or sees sparks. By the time flames appear, temperatures may already be high enough to cause flash ignition and rapid fire spread.

According to HSE electrical safety guidance, electrical fires are commonly caused by faulty wiring, overloading, poor insulation, inadequate maintenance, and misuse of electrical equipment.

Understanding the real causes of electrical fires is essential, not just for electricians and safety officers, but for anyone responsible for buildings, machines, or electrical systems. This guide explains why electrical fires start, how they grow unnoticed, and what conditions turn small faults into major fire incidents.

Why Electrical Fires Are So Dangerous

Unlike open-flame fires, electrical fires:

- Start in concealed locations

- Develop without visible warning

- Generate extreme heat very quickly

- Often ignite surrounding materials simultaneously

Because of this, electrical fires are responsible for some of the fastest-spreading and most destructive fires in homes, offices, and industrial facilities.

How Electrical Energy Turns Into Fire

Electricity itself does not burn.

Fire starts when electrical energy is converted into uncontrolled heat.

This happens when:

- Too much current flows

- Resistance increases at a connection

- Electricity jumps through air as an arc

- Insulation breaks down

- Equipment overheats beyond safe limits

Once surrounding materials reach ignition temperature, fire begins.

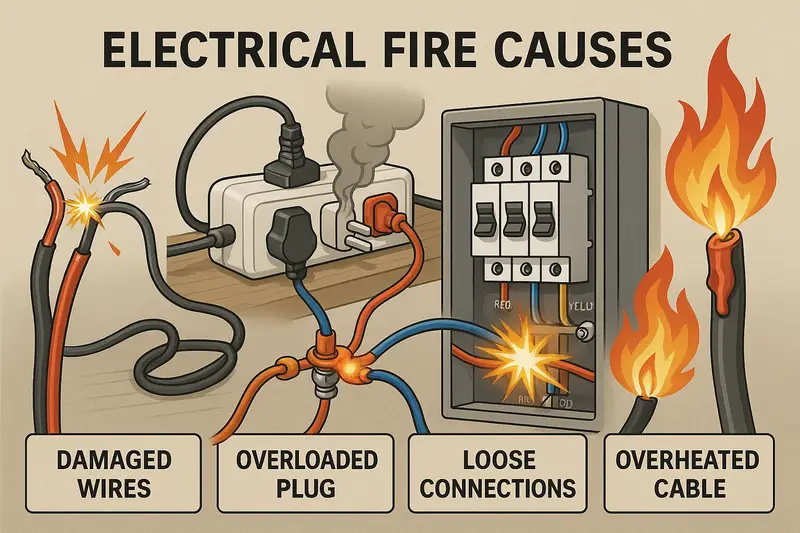

The Most Common Electrical Fire Causes

1. Loose Electrical Connections

Loose connections are one of the leading causes of electrical fires.

When a connection loosens:

- Electrical resistance increases

- Heat builds up at the joint

- Insulation begins to carbonize

- Arcing starts under load

These hot spots often develop inside panels, sockets, or motor terminals where they remain hidden until ignition occurs.

2. Overloaded Circuits

Electrical circuits are designed for a specific load.

When that limit is exceeded, cables and terminals overheat.

Common overloading situations include:

- Multiple high-power appliances on one socket

- Continuous operation of heavy equipment

- Temporary extensions used permanently

- Undersized wiring in older buildings

Overloading causes slow overheating, which is why fires may occur hours after appliances are switched on.

3. Short Circuits

A short circuit occurs when live conductors come into unintended contact.

This causes:

- Instant current surge

- Intense arcing

- Molten metal particles

- Ignition of insulation and nearby materials

Short circuits are often triggered by damaged insulation, moisture ingress, rodent damage, or failed appliances.

4. Electrical Arcing

Arcing happens when electricity jumps across gaps instead of flowing through a conductor.

Why arcing is dangerous:

- Arc temperatures can exceed several thousand degrees

- Even tiny arcs can ignite dust and insulation

- Arcing often occurs intermittently, making detection difficult

Many electrical fires are actually arc-initiated fires, not direct short circuits.

5. Faulty or Aging Wiring

Electrical wiring does not last forever.

Over time:

- Insulation becomes brittle

- Conductors loosen due to thermal cycling

- Joints degrade

- Protective devices lose effectiveness

Buildings with old wiring are at significantly higher risk, especially if load demand has increased since installation.

6. Overheating Electrical Equipment

Motors, transformers, UPS systems, and appliances all generate heat during normal operation.

Fires occur when:

- Ventilation is blocked

- Dust accumulates inside equipment

- Cooling fans fail

- Equipment operates beyond rated capacity

Overheated components can ignite internal insulation, oil residues, or nearby combustibles.

7. Poor Quality or Counterfeit Electrical Components

Low-quality electrical products are a hidden fire risk.

These often fail because:

- Conductors are undersized

- Insulation quality is poor

- Protective devices do not trip correctly

- Contacts degrade rapidly under load

In many fire investigations, circuit breakers were found not to operate during faults, allowing ignition to occur.

8. Cable Overheating in Concealed Spaces

Cables running through walls, ceilings, and conduits are vulnerable when:

- Too many cables are grouped together

- Heat cannot dissipate

- Load is continuous

- Cables pass through insulation materials

These fires are particularly dangerous because they spread invisibly through building cavities.

9. Environmental Factors

Electrical systems are highly sensitive to their surroundings.

Common environmental contributors include:

- Moisture causing insulation failure

- Dust acting as combustible fuel

- Corrosion increasing resistance

- Vibration loosening terminals

- Rodents chewing insulation

These factors accelerate electrical degradation and ignition risk.

How Electrical Fires Develop Step by Step

Most electrical fires follow a predictable pattern:

- Minor defect develops

Loose screw, worn insulation, small overload. - Heat slowly builds up

Often unnoticed for weeks or months. - Insulation begins to degrade

Carbonization makes insulation conductive. - Arcing starts

High-energy sparks appear intermittently. - Ignition occurs

Surrounding materials catch fire rapidly.

This progression explains why electrical fires often seem sudden, even though the fault existed long before.

Warning Signs That Are Often Ignored

Many electrical fires provide early clues, such as:

- Burning smell near sockets or panels

- Warm switches or plugs

- Flickering lights

- Frequent breaker tripping

- Crackling or buzzing sounds

- Discolored outlets or cables

Ignoring these signs allows faults to grow until ignition occurs.

Why Electrical Standards Matter

Electrical codes exist because most fire causes are predictable.

Proper standards ensure:

- Correct cable sizing

- Reliable overcurrent protection

- Safe grounding

- Arc fault detection

- Safe installation methods

When installations follow recognized standards and are properly maintained, electrical fire risk drops dramatically.

Real-World Lessons From Fire Investigations

Fire investigations repeatedly show that:

- Fires started at loose terminals

- Overloaded circuits were common

- Cheap components failed to protect

- Inspections were skipped or delayed

In many cases, simple preventive maintenance would have prevented the fire entirely.

How Electrical Fires Can Be Prevented

Effective prevention focuses on:

- Proper system design

- Certified materials

- Regular inspections

- Thermal scanning of panels

- Tightening of connections

- Cleaning dust and debris

- Managing electrical loads

- Replacing aged wiring

Electrical safety is not a one-time activity, it is continuous.

Why Electrical Fire Prevention Is Everyone’s Responsibility

Electrical fires do not only affect electricians.

They impact:

- Occupants

- Business operations

- Production continuity

- Insurance costs

- Human lives

Understanding electrical fire causes helps people recognize risks before they turn into disasters.

Conclusion

Electrical fires are rarely accidents. They are the result of predictable faults such as loose connections, overloading, arcing, aging wiring, overheating equipment, and poor-quality components. These failures often develop quietly and remain hidden until ignition occurs.

By understanding how electrical fires start and recognizing early warning signs, facilities and individuals can take timely action. Proper installation, certified components, regular inspections, and proactive maintenance are the most effective tools for preventing electrical fires and protecting lives, property, and critical infrastructure.

Electrical Fire Safety: Causes, Controls, and Prevention Measures

Heat Sources in Industrial Fires: Causes, Risks, Control Measures and Prevention

Fuel Types and Their Fire Behaviour

Preventing Short-Circuit Fires: Causes, Controls, Protection Devices, and Safety Measures