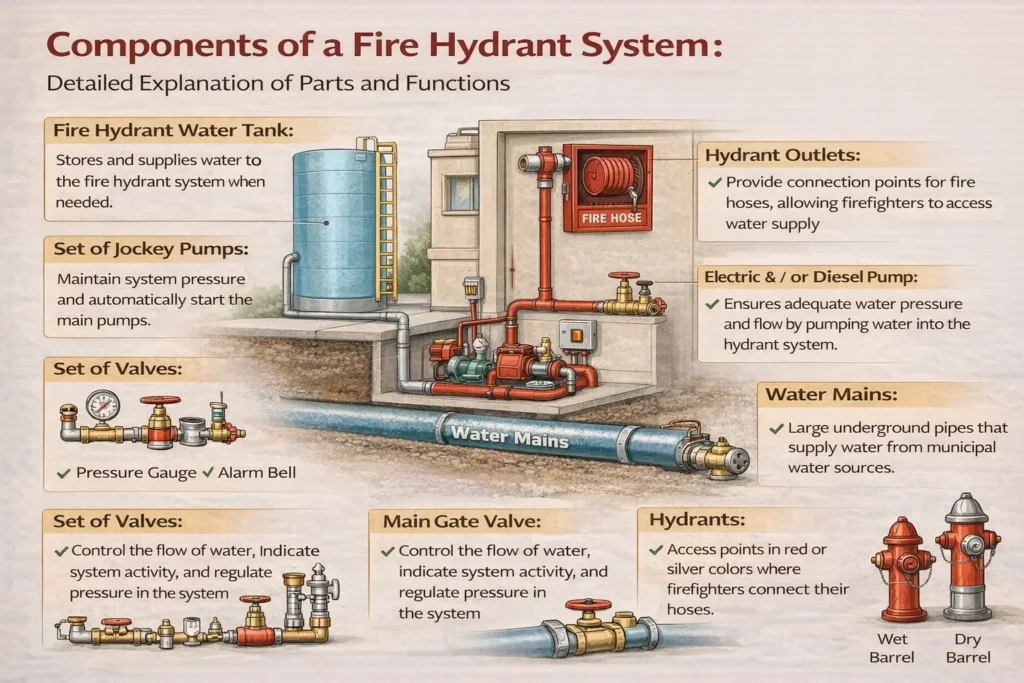

Components of a Fire Hydrant System, How Each Part Fails or Saves a Fire Response

A fire hydrant system looks impressive on drawings and inspection reports, but during a real fire, only one thing matters.

Does water reach the firefighter at the required pressure, immediately, and without failure?

Fire investigations repeatedly show that hydrant systems fail not because water is unavailable, but because one or more components do not function when needed. A closed valve, a non-starting pump, an empty tank, or a blocked hose can turn a well-designed system into a useless one.

According to HSE fire and explosion guidance, fire protection systems such as hydrants must be properly designed, installed, and maintained to ensure effective firefighting during emergencies.

This guide explains the components of a fire hydrant system from a real-world operational perspective, focusing on what each component does during an emergency, how it commonly fails, and why regular inspection is critical.

What a Fire Hydrant System Is Expected to Do During a Fire

In an actual emergency, a hydrant system must:

- Deliver large volumes of water continuously

- Maintain sufficient pressure at the outlet

- Allow firefighters to connect hoses quickly

- Operate automatically without human intervention

- Continue working even during power failure

Every component exists to support these outcomes. If one fails, the entire system is compromised.

The Pump Room, The Heart of the Hydrant System

The pump room is the single most critical area in any hydrant installation. If pumps do not start instantly, the hydrant network becomes a collection of empty pipes.

Main Fire Pump

The main pump provides the required pressure and flow.

In real fires, failure usually occurs due to:

- Electrical supply issues

- Improper controller settings

- Mechanical seizure from lack of testing

A pump that is not run regularly often fails during its first real demand.

Diesel Fire Pump

The diesel pump exists for one reason.

Fire does not wait for electricity to return.

Common failure points include:

- Weak batteries

- Empty or contaminated fuel tanks

- Cooling or exhaust system blockage

Diesel pumps must be tested under load, not just cranked briefly.

Jockey Pump

The jockey pump maintains pressure and prevents unnecessary main pump starts.

If it fails:

- Pressure drops slowly and unnoticed

- Main pump starts frequently

- System wear increases

- Delays occur during real demand

A malfunctioning jockey pump is often the first warning sign of a neglected system.

Fire Water Storage, The System’s Lifeline

No pump can perform without water.

Fire Water Tank

The fire tank must supply water for the entire expected firefighting duration.

Common issues found during audits:

- Tank partially empty

- Shared domestic connections

- Blocked suction outlets

- Faulty level indicators

During fires, empty or inaccessible tanks are a frequent cause of hydrant failure.

The Piping Network, How Water Reaches the Fire

Ring Main System

A ring main ensures water reaches hydrants even if one section is damaged.

If isolation valves are incorrectly positioned or damaged:

- Entire zones may lose water

- Firefighters may unknowingly connect to a dead line

Valve position control is as important as pipe size.

Riser Pipes in Buildings

In high-rise buildings, risers carry water vertically.

Failures commonly occur due to:

- Air locking

- Undersized pipes

- Poor pressure zoning

- Undetected leakage

Upper floors are often the first to lose pressure during real incidents.

Valves, Small Components With Huge Impact

Valves control, isolate, and protect the system.

Isolation Valves

If left partially closed or seized:

- Flow rate drops drastically

- Pressure readings become misleading

Poor valve tagging and maintenance are a major risk.

Non-Return Valves

These protect pumps from reverse flow.

If they fail:

- Pressure drops unexpectedly

- Pumps may spin backward

- System stability is lost

NRVs are often ignored because they are not visible during routine inspections.

Hydrant Valves and Outlets, Where Firefighters Depend on the System

Hydrant outlets are the only visible part of the system during a fire.

Common problems include:

- Jammed valve spindles

- Leakage under pressure

- Missing or incompatible couplings

- Obstructed access

A hydrant outlet that cannot be opened quickly is equivalent to no hydrant at all.

Hoses, Branch Pipes, and Nozzles, The Final Delivery Point

Fire Hoses

Hoses must withstand pressure and rough handling.

Frequent failures occur due to:

- Age related cracking

- Improper drying and storage

- Damaged couplings

Hoses are often the weakest physical link in the system.

Nozzles and Branch Pipes

Incorrect or damaged nozzles can:

- Reduce reach

- Waste water

- Make fire control ineffective

Firefighters rely on predictable spray patterns during high-stress situations.

Electrical and Control Systems, The Invisible Backbone

Hydrant systems depend heavily on automation.

Critical failures include:

- Faulty pressure switches

- Disabled auto-start functions

- Alarm panels not monitored

- Backup power not functional

A hydrant system that requires manual intervention is already at risk.

Fire Brigade Inlet, The Backup That Often Saves the Day

The fire brigade inlet allows external pumping support.

Common issues:

- Blocked or damaged inlets

- Missing caps or non-return valves

- Poor accessibility

In large fires, this inlet often determines whether pressure can be sustained.

Why Hydrant Systems Fail During Real Fires

Most failures are not design problems. They are maintenance and management failures, such as:

- Valves left closed after testing

- Pumps not tested under load

- Tanks used for non-fire purposes

- Hoses not pressure tested

- Electrical panels kept in manual mode

These issues remain hidden until a real emergency.

Inspection Focus Areas That Prevent Failure

Effective inspections always verify:

- Pumps start automatically

- Valves are fully open and tagged

- Tanks are full and isolated

- Pressure is available at the farthest hydrant

- Fire brigade inlets are functional

Paper compliance alone does not stop fires.

Who Should Use This Guide

This guide is written for:

- Safety officers and fire wardens

- Facility and maintenance managers

- Fire inspectors and auditors

- Industrial supervisors

- Building owners and occupiers

Understanding components is only useful when it improves readiness.

Conclusion

A fire hydrant system is only as reliable as its weakest component. Pumps, tanks, pipes, valves, hoses, controls, and inlets must all function together under extreme conditions. Most hydrant failures occur not because systems were poorly designed, but because components were neglected, isolated, or assumed to be working.

Effective fire safety is not about installing hydrants. It is about ensuring every component will perform instantly when lives depend on it.

Fire Hydrant System: Components, Working, Types, Installation and Maintenance

How to Operate a Fire Hydrant: Step-by-Step Procedure, Safety Rules, and Technical Guidelines