CO₂ Fire Extinguisher, Where It Works Perfectly and Where It Becomes Dangerous

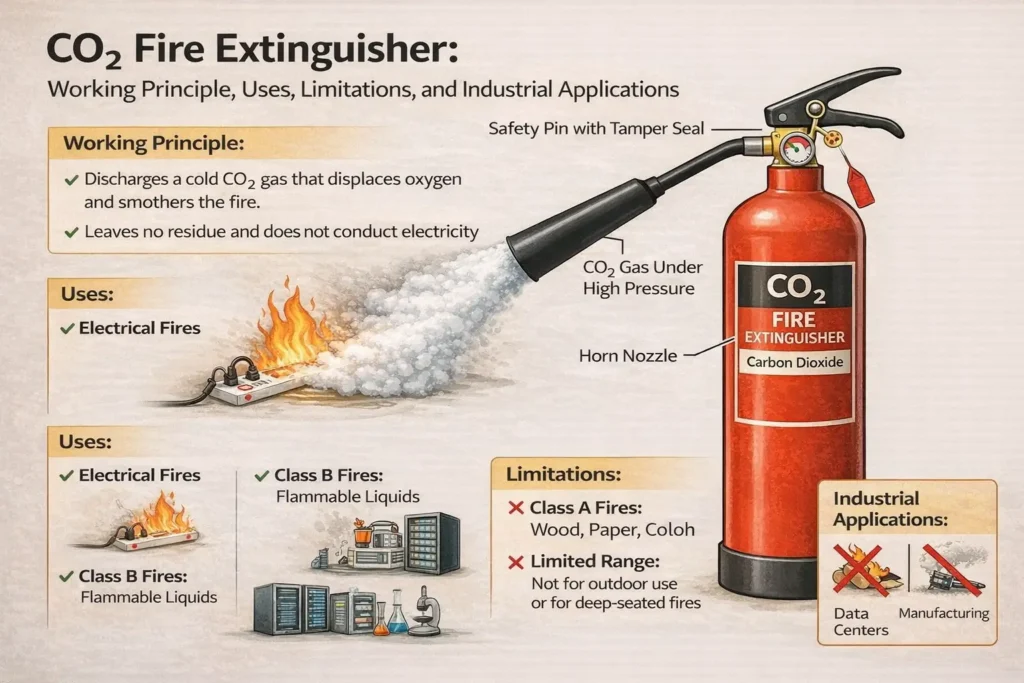

CO₂ fire extinguishers are widely installed in offices, server rooms, laboratories, electrical panels, and industrial facilities. They are often chosen because they leave no residue and do not damage equipment. However, fire investigations repeatedly show that CO₂ extinguishers are frequently misunderstood and misused, leading to re ignition, exposure risks, or delayed evacuation.

According to HSE fire and explosion guidance, carbon dioxide extinguishers work by displacing oxygen around the fire, which can create asphyxiation risks in enclosed or confined spaces.

This guide explains CO₂ fire extinguishers from a practical fire response perspective, focusing on when they are the best possible choice, when they should not be used, and what mistakes people commonly make during real incidents.

What a CO₂ Extinguisher Actually Does

A CO₂ extinguisher does not cool fuel effectively. Its primary function is to push oxygen away from the fire zone and dilute flammable vapours.

When CO₂ is released:

- Oxygen concentration drops rapidly around the flame

- Combustion becomes unsustainable

- Flames collapse almost instantly

This makes CO₂ extremely effective for small, localized fires, especially where cooling or residue is undesirable.

Fires Where CO₂ Works Best

CO₂ extinguishers perform best when:

- The fire is small and contained

- Oxygen can be displaced effectively

- The fuel surface is limited

They are ideal for:

- Electrical panels and switchgear

- Server rooms and data centers

- Control cabinets and UPS systems

- Laboratories with flammable solvents

- Small liquid spill fires

In these scenarios, water and foam can cause damage, while powder creates cleanup and equipment failure issues.

Why CO₂ Is Preferred for Electrical Fires

CO₂ is:

- Non conductive

- Non corrosive

- Residue free

This means it:

- Does not short circuit equipment

- Does not contaminate electronics

- Does not require costly cleanup

That is why CO₂ is commonly installed near live electrical equipment.

Why CO₂ Often Fails After Initial Success

One of the most common fire investigation findings is re ignition after CO₂ use.

This happens because:

- CO₂ does not cool the fuel significantly

- Hot surfaces remain above ignition temperature

- Once CO₂ disperses, oxygen returns

- Fire restarts from the same source

CO₂ extinguishes flames, not heat.

Fires Where CO₂ Should Not Be Used

CO₂ is a poor or dangerous choice for several fire types.

Ordinary Combustibles

On wood, paper, fabric, or furniture:

- Fire may go out briefly

- Smouldering continues

- Re ignition occurs quickly

Water or foam is far more effective in these cases.

Confined Spaces With People

CO₂ displaces oxygen. In small rooms:

- Breathing becomes difficult

- Dizziness and loss of consciousness can occur

- Evacuation may be delayed

CO₂ should never be used in confined spaces without immediate exit and ventilation.

Outdoor Fires

Wind disperses CO₂ quickly:

- Oxygen displacement is ineffective

- Fire continues burning

- Discharge is wasted

Gas Jet Fires

CO₂ cannot stop pressurized gas flow.

Fuel isolation is the only effective solution.

The Cold Discharge Hazard People Ignore

During discharge, CO₂ expands rapidly and becomes extremely cold.

Risks include:

- Frostbite from touching the horn

- Cold burns to hands and skin

- Loss of grip or control

Many injuries occur simply because users grab the horn instead of the handle.

Common CO₂ Extinguisher Mistakes Seen on Sites

Fire safety audits repeatedly identify:

- Using CO₂ on deep seated fires

- Discharging without isolating power or fuel

- Standing too close and freezing hands

- Remaining in the room after discharge

- Failing to ventilate the area

These mistakes often occur because people overestimate CO₂ effectiveness.

How to Use CO₂ Safely in Real Situations

Good practice includes:

- Confirm the fire is electrical or flammable liquid

- Keep one hand on the handle only

- Aim at the base, not the flames

- Maintain distance of at least 1.5 meters

- Watch for re ignition after discharge

- Ventilate immediately after use

If flames return, switch to a cooling or smothering agent if safe.

Where CO₂ Extinguishers Are Essential

CO₂ extinguishers are strongly recommended in:

- Server rooms and IT facilities

- Control panels and MCC rooms

- Laboratories and testing rooms

- Marine engine rooms

- Aviation maintenance areas

- Printing presses and instrumentation zones

In these environments, residue free suppression is critical.

Maintenance Issues That Reduce Effectiveness

CO₂ extinguishers do not have pressure gauges.

Common problems found during inspections:

- Loss of CO₂ charge due to slow leakage

- Weight below minimum tolerance

- Damaged horns or hoses

- Corroded valves

- Overdue hydro testing

A CO₂ extinguisher that looks fine may be empty.

Who Should Use This Guide

This guide is intended for:

- Safety officers and fire wardens

- Facility and maintenance managers

- IT and laboratory staff

- Electrical supervisors

- Emergency response teams

Conclusion

CO₂ fire extinguishers are powerful tools when used in the right situation. They are unmatched for electrical fires and small flammable liquid fires where equipment protection is critical. At the same time, they provide little cooling, carry re ignition risk, and introduce serious hazards in confined spaces.

Effective fire safety is not about choosing the cleanest extinguisher. It is about choosing the correct extinguisher for the fire you are facing and knowing its limits.

Types of Fire Extinguishers: Complete Guide to Uses, Classes, Color Codes and Selection

Water Extinguisher: Uses and Limitations

Foam Fire Extinguishers and AFFF Explained: Working, Types, Uses, and Limitations

Dry Chemical Powder DCP Fire Extinguisher: Full Guide on Types, Working, Uses, and Limitations