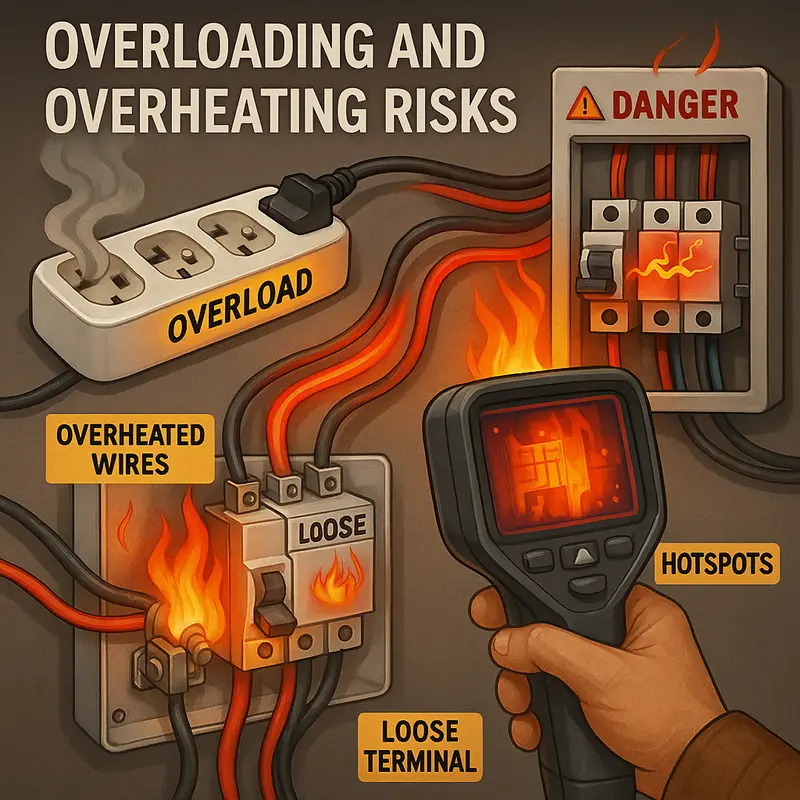

Overloading and Overheating Risks: How Electrical Systems Catch Fire and How to Prevent It

Electrical overloading and overheating are among the most common causes of electrical fires in homes, offices, and industrial facilities. These fires rarely start with sparks or explosions. Instead, they develop quietly over time inside wiring, switchboards, sockets, extension cords, and electrical panels until temperatures rise high enough to ignite insulation or nearby materials.

According to HSE electrical safety guidance, overloading electrical circuits and poor heat dissipation can lead to overheating, insulation failure, and increased fire risk.

Modern buildings use more electrical devices than ever before. Heaters, air conditioners, computers, servers, motors, and automation equipment all place heavy demands on electrical systems. When circuits are pushed beyond their design limits or heat is unable to escape, the result is overheating and eventually fire.

This guide explains how overloading and overheating actually happen, why they are dangerous, and what practical steps prevent them.

What Is Electrical Overloading?

Electrical overloading occurs when a circuit, cable, socket, or device carries more current than it was designed to handle.

Every electrical component has a safe operating limit. When this limit is exceeded:

- Wires heat up

- Insulation weakens

- Connections loosen

- Protective devices trip, or fail to trip

Overloading may happen suddenly or develop slowly over weeks or months.

What Is Electrical Overheating?

Overheating is excessive temperature buildup in wiring or equipment. It does not always require overloading.

Overheating can occur due to:

- Loose connections

- Corrosion

- Poor ventilation

- Damaged insulation

- Continuous operation at high load

Even normal current can cause dangerous heating if resistance increases at connection points.

How Overloading and Overheating Lead to Fires

Overloading and overheating reinforce each other.

Heat Generation in Electrical Systems

When current flows through a conductor, heat is produced naturally. Under safe conditions, this heat dissipates. When current increases or resistance rises, heat builds faster than it can escape.

Expansion and Loose Connections

As wires heat up:

- Metal expands

- Terminal screws loosen

- Contact area reduces

- Resistance increases further

This creates localized hot spots.

Insulation Breakdown

Prolonged heating damages insulation. Once insulation cracks or melts:

- Conductors become exposed

- Arcing begins

- Flames ignite nearby materials

Most electrical fires begin inside concealed spaces where overheating goes unnoticed.

Common Causes of Electrical Overloading

Too Many Devices on One Circuit

This is the most common cause in homes and offices.

Examples include:

- Heater, kettle, and microwave on one outlet

- Multiple computers on a weak circuit

- Heavy appliances connected through extension boards

Undersized Wiring

Thin wires cannot safely carry high current. Even if breakers do not trip, overheating occurs internally.

Continuous Heavy Loads

Equipment that runs for long periods, such as:

- Water heaters

- Air conditioners

- Industrial motors

- Welding machines

places constant stress on wiring.

Poor-Quality Electrical Accessories

Cheap extension cords, adapters, and sockets overheat faster and often fail without warning.

Common Causes of Electrical Overheating

Loose Electrical Connections

Loose terminals are the number one cause of electrical fires.

They create:

- High resistance

- Micro-arcing

- Rapid localized heating

Poor Ventilation

Heat becomes trapped when:

- Panels are enclosed

- Equipment rooms lack airflow

- Power strips are covered by furniture or carpets

Aging Electrical Systems

Old wiring loses insulation strength and cannot handle modern electrical demand.

Corrosion and Dust

Corrosion increases resistance. Dust acts as fuel once ignition begins.

Warning Signs of Overloading and Overheating

Early signs almost always appear before a fire.

Visual Warning Signs

- Burn marks on sockets

- Melted plugs

- Discolored switch plates

- Deformed extension cords

Thermal Warning Signs

- Warm outlets or switches

- Hot power strips

- Burning smell

Electrical Behavior Signs

- Frequent breaker tripping

- Flickering lights

- Buzzing sounds from panels

- Equipment shutting down unexpectedly

Ignoring these signs allows the problem to escalate.

High-Risk Locations for Overloading and Overheating

Homes

- Old buildings with outdated wiring

- Kitchens with multiple appliances

- Bedrooms using heaters and extension boards

Offices

- Server rooms

- Printing and copying areas

- Workstations with many devices

Industrial Facilities

- Motor control centers

- Temporary construction panels

- Transformer and electrical rooms

Industrial environments are especially vulnerable due to continuous high loads.

How to Prevent Electrical Overloading and Overheating

Use Proper Cable Sizes

Correct cable sizing prevents excessive heating. Heavy appliances must always have dedicated circuits.

Never rely on extension cords for high-power devices.

Install Correct Protective Devices

Protection devices must match the wiring and load.

These include:

- Circuit breakers for overload and short circuits

- Leakage protection for insulation failure

- Industrial breakers for high-current equipment

Incorrect or bypassed protection defeats all safety.

Avoid Permanent Use of Extension Boards

Extension boards are temporary solutions. Long-term use causes:

- Heating

- Plug melting

- Internal arcing

High-wattage appliances should always connect directly to wall outlets designed for the load.

Balance Electrical Loads

Spread high-load devices across multiple circuits instead of concentrating them on one line.

Ensure Ventilation Around Electrical Equipment

Panels, power strips, and electrical rooms must release heat freely. Trapped heat accelerates insulation failure.

Replace Old or Damaged Wiring

Wiring older than 15 to 20 years often cannot support modern electrical demand and should be upgraded.

Tighten Electrical Connections Regularly

Loose terminals cause most overheating incidents. Periodic tightening is essential in:

- Distribution boards

- Industrial panels

- Motor terminals

Use Thermal Inspection Where Possible

Thermal scanning detects:

- Hot spots

- Loose connections

- Overloaded circuits

This is especially important in industrial and commercial buildings.

Overloading Risks in Industrial Systems

Industrial electrical systems face higher danger because:

- Loads run continuously

- Fault currents are higher

- Equipment generates more heat

Special care is required in:

- Motor control centers

- Welding circuits

- Temporary power panels

Routine inspection prevents catastrophic failures.

Consequences of Ignoring Overloading and Overheating

Failure to control these risks leads to:

- Electrical fires

- Equipment destruction

- Electrical shock hazards

- Business downtime

- Legal liability for owners and managers

Most electrical fire investigations trace the cause back to overheating that was visible earlier.

Real-Life Fire Examples

- Homes have burned due to heaters plugged into extension boards.

- Offices have lost server rooms due to overloaded circuits.

- Factories have suffered major losses due to loose terminals in control panels.

All were preventable with basic electrical safety practices.

Conclusion

Electrical overloading and overheating are silent hazards that develop long before flames appear. They result from excessive load, poor connections, inadequate ventilation, and aging infrastructure. The good news is that these risks are entirely preventable.

By using correctly sized wiring, avoiding overloads, maintaining tight electrical connections, ensuring proper ventilation, and responding early to warning signs, electrical fires can be eliminated before they start.

Electrical safety is not about reacting to fires. It is about preventing heat from becoming ignition in the first place.

Electrical Fire Safety: Causes, Controls, and Prevention Measures

Electrical Fire Causes: Detailed Explanation, Scientific Background, Risk Factors, and Prevention

Preventing Short-Circuit Fires: Causes, Controls, Protection Devices, and Safety Measures