Safe Wiring Practices: How Proper Electrical Wiring Prevents Fires and Electrical Accidents

Safe wiring practices form the foundation of electrical safety in homes, offices, commercial buildings, and industrial facilities. Most electrical fires do not start because of faulty appliances. They begin silently inside walls, distribution boards, cable trays, or conduits due to poor wiring design, incorrect installation, or neglected maintenance.

When wiring is done correctly, electrical systems remain stable, protective devices work as intended, and fire risk drops dramatically. When wiring is unsafe, even a small fault can escalate into overheating, arcing, short circuits, or a full-scale fire.

According to HSE electrical safety guidance, safe wiring practices, correct installation, and regular inspection are essential to prevent electrical faults and fire hazards.

This guide explains safe wiring practices in a practical, real-world way, focusing on how fires actually start and how correct wiring prevents them.

Why Safe Wiring Is Critical for Fire Prevention

Electricity always generates heat. Safe wiring ensures that this heat stays within safe limits and does not damage insulation or surrounding materials.

Proper wiring:

- Prevents overheating of conductors

- Ensures breakers trip during faults

- Reduces short-circuit and arc-fault risk

- Protects appliances and equipment

- Keeps people safe from shock and fire

Unsafe wiring allows heat to build up unnoticed, often inside concealed spaces where fires spread rapidly before detection.

How Unsafe Wiring Leads to Electrical Fires

Electrical fires usually follow a predictable pattern:

- Poor wiring increases resistance

- Resistance generates heat

- Heat degrades insulation

- Conductors touch or arc

- Ignition occurs

Common consequences of unsafe wiring include:

- Melted insulation

- Hidden short circuits

- Arc faults inside walls

- Fire spread through ceilings and cable routes

- Complete system failure

These failures often occur months or years after installation, making prevention far more important than reaction.

Choosing the Right Electrical Cables

Correct Cable Size Matters

Cable size must always match the electrical load. Undersized cables overheat even when breakers do not trip.

As a general guideline:

- Lighting circuits require smaller conductors

- Socket outlets require heavier cables

- High-power appliances need dedicated circuits

- Industrial equipment requires load-calculated sizing

Correct sizing prevents continuous heating and insulation breakdown.

Copper vs Aluminum Conductors

Copper wiring is preferred because it:

- Carries current more efficiently

- Heats less

- Handles vibration better

- Maintains tight connections longer

Aluminum wiring can be safe only if:

- Properly sized

- Correctly terminated

- Periodically inspected

Poor aluminum terminations are a known fire risk.

Fire-Resistant Cable Types

Modern installations should use fire-safe cables such as:

- Fire-retardant

- Low-smoke

- Low-toxicity insulation

These cables do not stop fires, but they:

- Reduce flame spread

- Limit toxic smoke

- Improve evacuation safety

Safe Wiring Installation Practices

Avoid Overcrowding Conduits and Panels

When too many cables are packed together:

- Heat cannot escape

- Insulation temperature rises

- Cable life shortens

- Fire risk increases

Proper spacing allows natural heat dissipation.

Protect Cables from Physical Damage

Cables must be protected from:

- Sharp metal edges

- Abrasion

- Crushing

- Rodents

Bushings, sleeves, and conduits prevent insulation damage that leads to short circuits.

Maintain Proper Bending Radius

Excessive bending damages internal conductors and insulation. Damaged cables often fail months later, not immediately.

Correct Identification and Color Coding

Clearly identified wiring:

- Prevents incorrect connections

- Reduces maintenance errors

- Helps protective devices work correctly

Incorrect or mixed wiring colors are a frequent cause of dangerous faults.

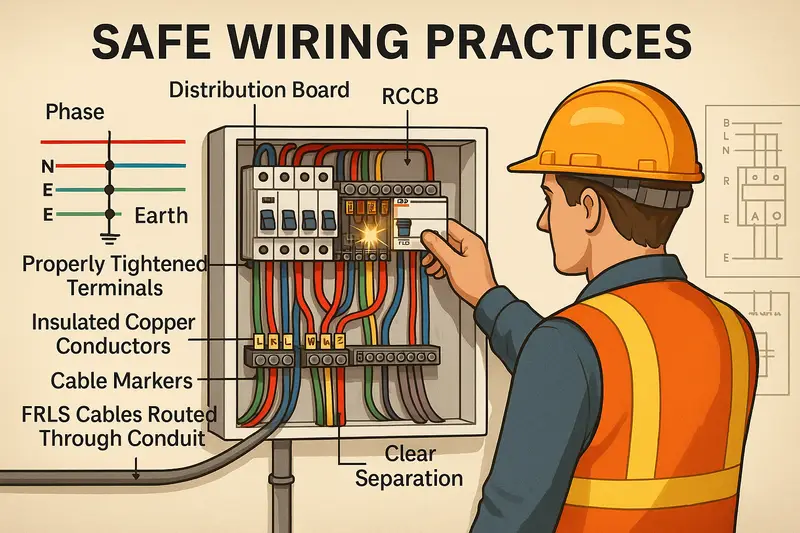

Safe Wiring Inside Distribution Boards

Distribution boards are common fire origin points.

Safe practices include:

- Tightening terminals to correct torque

- Using lugs or ferrules instead of bare wires

- Keeping wiring neat and organized

- Avoiding overcrowding

- Ensuring ventilation inside panels

Loose or messy panels trap heat and promote arcing.

Importance of Proper Grounding and Earthing

Grounding provides a safe path for fault current.

Proper earthing:

- Allows breakers to trip quickly

- Prevents electric shock

- Reduces arc energy

- Protects metal enclosures

Poor or missing earthing allows faults to persist long enough to start fires.

Safe Wiring in Different Environments

Homes

Safe wiring in homes includes:

- Dedicated circuits for heavy appliances

- Leakage protection for wet areas

- Quality switches and sockets

- No permanent extension board use

- Regular inspection of outlets

Most residential fires start at overloaded or poorly wired sockets.

Offices and Commercial Buildings

Offices require:

- Proper cable management

- Fire-safe cables in server rooms

- Adequate ventilation for wiring ducts

- Periodic testing of protection devices

Hidden wiring failures often cause after-hours office fires.

Industrial Facilities

Industrial wiring must address:

- Vibration

- Dust

- Moisture

- High fault energy

Best practices include:

- Armored cables for machinery

- Proper cable tray spacing

- Thermal scanning of panels

- Strong grounding systems

Industrial wiring failures often escalate rapidly due to high power levels.

Protective Devices That Support Safe Wiring

Wiring safety depends on correct protection.

Key devices include:

- Circuit breakers for overload and short circuits

- Leakage protection for insulation failure

- Surge protection for voltage spikes

- Arc fault protection for loose or damaged wiring

Wiring alone cannot prevent fires if protection devices are missing or defective.

Testing and Inspection for Wiring Safety

Safe wiring must be verified, not assumed.

Essential tests include:

- Insulation resistance testing

- Continuity checks

- Ground resistance measurement

- Breaker and leakage device testing

Regular testing detects faults long before ignition.

Warning Signs of Unsafe Wiring

Immediate attention is required if you notice:

- Burning smells

- Warm switches or outlets

- Flickering lights

- Frequent breaker trips

- Buzzing sounds

- Discolored wiring or sockets

These signs indicate active heating or arcing.

Common Wiring Mistakes That Cause Fires

Frequent fire-causing mistakes include:

- Using undersized cables

- Leaving loose terminations

- Ignoring earthing

- Overloading sockets

- Poor cable routing

- Using cheap, non-certified components

Most are preventable with basic discipline.

Conclusion

Safe wiring practices are not optional technical details. They are the primary defense against electrical fires, equipment damage, and electric shock. Correct cable selection, proper installation, reliable grounding, effective protection devices, and routine inspection work together to keep electrical systems safe throughout their service life.

Whether in homes, offices, or industrial facilities, safe wiring protects lives, property, and business continuity. Electrical fires rarely happen without warning. Safe wiring ensures those warnings never become disasters.

Electrical Fire Safety: Causes, Controls, and Prevention Measures

Heat Sources in Industrial Fires: Causes, Risks, Control Measures and Prevention

Electrical Fire Causes: Detailed Explanation, Scientific Background, Risk Factors, and Prevention

Preventing Short-Circuit Fires: Causes, Controls, Protection Devices, and Safety Measures

Overloading and Overheating Risks: Causes, Safety Tips, Prevention