How to Operate a Fire Hydrant Safely During an Emergency

A fire hydrant can deliver thousands of liters of water per minute, but during real emergencies, hydrants often fail to control fires not because of poor design, but because they are operated incorrectly. Sudden valve opening, poor hose control, lack of coordination, or improper nozzle use can turn a firefighting attempt into a dangerous situation within seconds.

According to HSE fire and explosion guidance, firefighting equipment such as fire hydrant systems must be operated safely by trained personnel and maintained to ensure reliability during emergencies.

This guide explains how a fire hydrant is actually operated during emergencies, focusing on safe handling, pressure control, teamwork, and the common mistakes that cause injuries or system damage. It is written for safety officers, industrial teams, facility staff, and anyone expected to use hydrants before the fire brigade arrives.

What Happens When a Hydrant Is Opened

When a hydrant valve is opened, pressurized water rapidly fills the hose line. This creates:

- High internal pressure

- Strong reaction force at the nozzle

- Sudden movement of the hose if not controlled

If the valve is opened too quickly or without coordination, hoses can whip, couplings can fail, and operators can lose balance. Understanding this behavior is the first step to safe hydrant operation.

When a Fire Hydrant Should Be Used

Hydrants are typically operated:

- During early-stage fires before brigade arrival

- To protect escape routes

- To cool nearby equipment or structures

- During industrial fire response

- During fire drills and system testing

Hydrants are not intended for small incipient fires where portable extinguishers are sufficient.

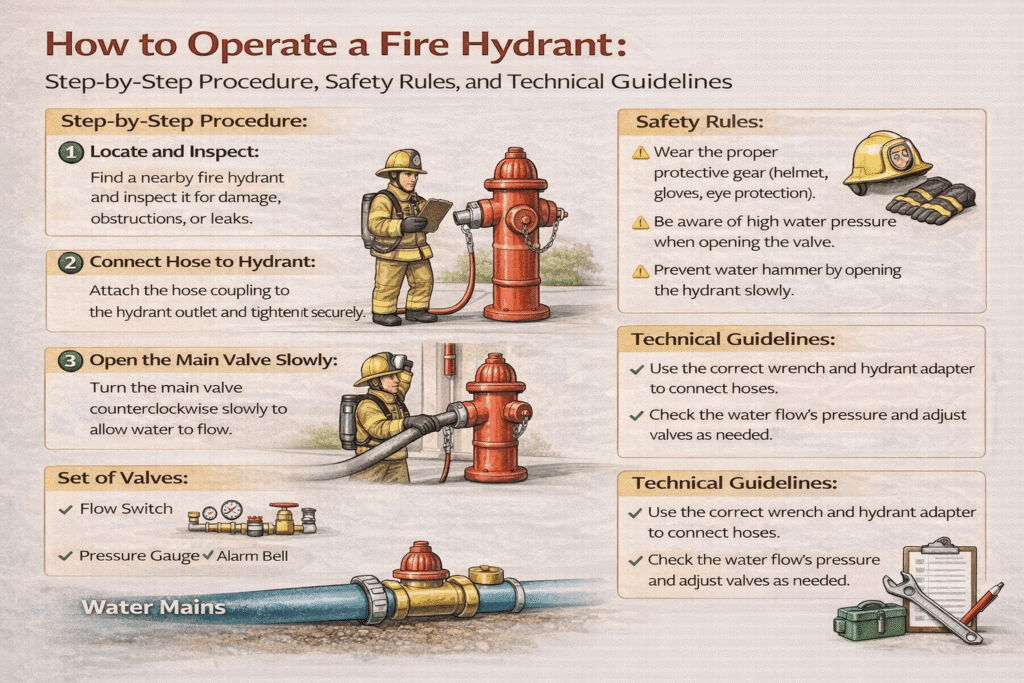

Basic Equipment Needed Before Operation

Before operating any hydrant, the following must be ready:

- Fire hose in good condition

- Branch pipe and nozzle properly fitted

- Hydrant valve key

- Personal protective equipment such as helmet, gloves, and safety shoes

Attempting hydrant operation without protective equipment increases injury risk significantly.

Checking the Hydrant Before Opening It

A quick inspection prevents many failures.

Always check:

- The valve spindle moves freely

- No visible leakage or damage

- Hose couplings lock properly

- Hose is not cracked or brittle

- Nozzle opening is clear

Many hydrant failures occur simply because hoses or valves were never checked during normal conditions.

Correct Way to Connect the Hose

The hose must be connected firmly to the hydrant outlet before opening the valve.

Key points:

- Ensure the coupling locks fully

- Avoid cross-threading or partial engagement

- Keep the nozzle closed before charging the hose

A loosely connected hose can disconnect violently under pressure.

Laying the Hose Correctly

Poor hose layout causes pressure loss and kinks.

Best practices:

- Lay the hose as straight as possible

- Avoid sharp bends and door edges

- Keep the hose away from vehicle movement

- Do not stand on the hose

A twisted hose reduces water flow and increases internal stress.

Why Communication Is Critical

Hydrant operation is never a one-person task.

Before opening the valve:

- The nozzle operator must confirm readiness

- The valve operator must open the hydrant only on instruction

A simple verbal confirmation prevents uncontrolled discharge and injuries.

Opening the Hydrant Valve Safely

The hydrant valve must always be opened slowly.

Why slow opening matters:

- Prevents water hammer

- Reduces hose shock

- Allows nozzle operator to control reaction force

Sudden opening is one of the most common causes of hose burst incidents.

Handling the Nozzle Under Pressure

Once water flows, the nozzle produces strong backward force.

Safe handling technique:

- Maintain a stable stance

- Keep both hands on the nozzle

- Brace your body against the reaction

- Avoid pointing the nozzle upward or sideways

Loss of nozzle control can injure nearby personnel.

Choosing the Right Nozzle Pattern

Different situations require different spray patterns.

Jet stream is used:

- For long-distance firefighting

- In open outdoor areas

Spray pattern is used:

- For cooling surfaces

- For wide fire coverage

Fog pattern is used:

- For heat protection

- For vapor suppression

- In confined or hazardous environments

Incorrect nozzle selection reduces firefighting effectiveness.

Moving Forward With a Charged Hose

A charged hose becomes heavy and difficult to control.

Safe advancement requires:

- One operator controlling the nozzle

- Another supporting the hose

- Slow, coordinated movement

Trying to advance alone often leads to loss of balance or fatigue.

Closing the Hydrant After Use

Shutdown must be controlled just like startup.

Correct sequence:

- Close the nozzle first

- Slowly close the hydrant valve

- Avoid sudden shutoff

Sudden closure can damage pipes and couplings.

Draining and Storing the Hose

After use:

- Drain water completely

- Dry the hose to prevent fungal growth

- Rewind properly

Wet or poorly stored hoses deteriorate quickly and fail during emergencies.

Common Hydrant Operation Mistakes

Most incidents happen due to:

- Opening the valve too fast

- Poor communication

- Kinked or twisted hoses

- Wrong nozzle selection

- Operating without PPE

These mistakes are preventable through regular drills and supervision.

Hydrant Operation in Industrial Areas

Industrial fires present additional risks:

- Flammable vapors

- Chemical exposure

- High radiant heat

In such environments:

- Fog patterns are preferred

- Distance must be maintained

- Cooling nearby equipment is critical

Never direct a jet stream into unknown chemical spills.

Why Training Matters More Than Equipment

A hydrant system may be perfectly designed, but without trained users:

- Pressure is mismanaged

- Hoses fail

- Water is wasted

- Fire spreads uncontrollably

Regular hands-on drills are the only way to ensure safe and effective operation.

Conclusion

Operating a fire hydrant is a physically demanding and technically sensitive task. High-pressure water can either save lives or create serious hazards depending on how it is handled. Safe hydrant operation depends on preparation, communication, controlled valve operation, proper nozzle use, and teamwork.

A hydrant is not just a valve and hose, it is a system that demands respect, training, and disciplined operation to be effective during emergencies.

Fire Hydrant System: Components, Working, Types, Installation and Maintenance

Water Extinguisher: Uses and Limitations

Components of a Fire Hydrant System: Detailed Explanation of Parts and Functions