Fire Hydrant System Explained, How It Works, Why It Fails, and How to Keep It Fire Ready

During major fire incidents, portable fire extinguishers are rarely enough. Once a fire grows beyond the initial stage, a reliable fire hydrant system becomes the primary firefighting tool. However, site inspections and real fire incidents repeatedly show that many hydrant systems fail not because they are absent, but because they are poorly designed, poorly maintained, or misunderstood.

According to HSE fire safety guidance, workplaces must provide suitable fire protection systems and ensure they are properly installed and maintained.

This guide explains the fire hydrant system from a real workplace and inspection perspective, focusing on how it works during emergencies, common failure points, and practical maintenance actions.

What a Fire Hydrant System Does in Real Emergencies

A fire hydrant system supplies large volumes of pressurized water to control or suppress fires that cannot be handled by portable extinguishers. It supports:

- Internal firefighting teams

- Fire brigade operations

- Large area fire coverage

- Prolonged firefighting duration

In high rise buildings, industrial plants, warehouses, and large campuses, the hydrant system is the backbone of fire protection.

Why Hydrant Systems Fail During Fires

From field observations, hydrant systems usually fail due to:

- Pumps not starting automatically

- Insufficient water pressure at hydrant points

- Blocked or leaking pipelines

- Non functional diesel backup pumps

- Poor hose and valve condition

- Lack of regular testing

Understanding these failures is more important than memorizing components.

Types of Fire Hydrant Systems and Where They Are Used

Wet Riser Systems

Wet risers remain charged with water at all times and are commonly used in:

- High rise buildings

- Hospitals

- Large commercial complexes

Key advantage: Immediate water availability

Common failure: Pressure loss due to leaks or faulty jockey pump

Dry Riser Systems

Dry risers remain empty until connected to a fire brigade pump.

Used in:

- Low rise buildings

- Areas with limited water storage

Common failure: Inlet valves inaccessible or blocked during emergencies

External Hydrant Systems

Installed outdoors to protect:

- Open yards

- Warehouses

- Industrial plants

- Tank farms

Common failure: Hydrants blocked by vehicles or vegetation

Internal Hydrant Systems

Installed inside buildings, usually near staircases and escape routes.

Common failure: Hose reels missing, damaged, or obstructed

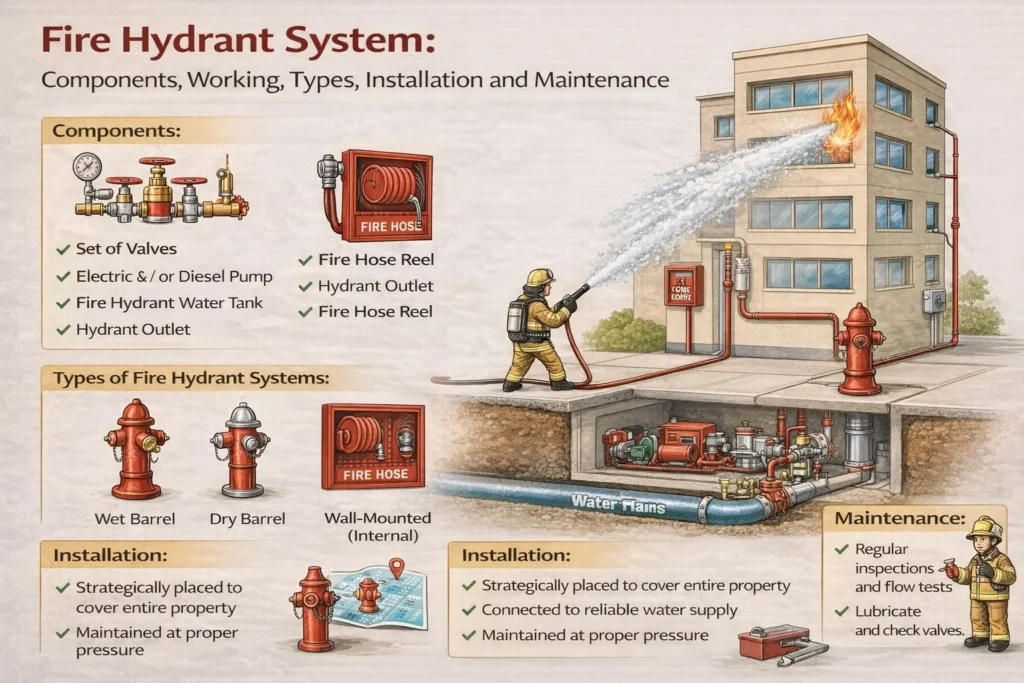

Core Components and Why Each One Matters

Fire Water Storage

The fire water tank ensures uninterrupted supply.

Common inspection issues:

- Fire water shared with domestic use

- Insufficient capacity

- Isolation valves left closed

Pump Room and Pumps

The pump room is the heart of the hydrant system.

Main pumps include:

- Electric pump for normal operation

- Diesel pump for power failure backup

- Jockey pump for pressure maintenance

Common failure: Diesel pump battery discharged or fuel unavailable

Hydrant Valves and Hose Systems

Hydrant valves allow firefighters to connect hoses and control water flow.

Common failure: Corroded valves, leaking glands, seized hand wheels

Fire Brigade Inlet

Allows external firefighting teams to pump water directly into the system.

Common failure: Inlet couplings damaged or inaccessible

How a Fire Hydrant System Operates During a Fire

- Jockey pump maintains system pressure

- Opening a hydrant causes pressure drop

- Pressure switch starts the main pump automatically

- Water flows through pipelines to hydrant outlets

- Diesel pump activates if electrical supply fails

If any one of these steps fails, firefighting is delayed.

Installation Factors That Directly Affect Performance

Poor installation is a major reason for hydrant system failure.

Critical factors include:

- Proper pipe sizing and support

- Correct placement of hydrant points

- Adequate pump room ventilation

- Reliable power and diesel backup

- Clear access to all hydrants

Incorrect installation often remains unnoticed until an emergency.

Practical Hydrant System Testing That Actually Matters

Pump Testing

- Automatic start on pressure drop

- Manual start verification

- Diesel pump load testing

Flow Testing

- Adequate discharge at farthest hydrant

- Pressure verification under flow conditions

Hose and Valve Testing

- Smooth valve operation

- No hose leakage

- Proper nozzle spray pattern

Testing without flow does not confirm readiness.

Maintenance Practices That Prevent Failure

Daily Checks

- Pump room cleanliness

- Pressure gauge readings

- Diesel fuel level

Weekly Checks

- Pump auto start test

- Jockey pump operation

- Valve accessibility

Monthly Checks

- Hose reel operation

- Hydrant valve inspection

- Strainer cleaning

Annual Checks

- Full flow test

- Pressure verification

- System audit

Most failures occur due to skipped routine checks.

Common Real World Problems Seen During Audits

- Pumps in manual mode instead of auto

- Fire water valves closed unknowingly

- Hose reels missing nozzles

- Diesel pumps not maintained

- Hydrant points blocked by storage

These issues turn a critical life safety system into a false sense of security.

Advantages of a Properly Maintained Hydrant System

- Continuous firefighting capability

- Suitable for large fires

- Supports fire brigade operations

- Essential for high risk buildings

- Designed for long duration firefighting

Limitations to Understand Clearly

- Not suitable for live electrical fires

- Requires trained operators

- Water damage possible

- Ineffective for metal and oil pool fires without support systems

Who Should Use This Guide

This guide is intended for:

- Safety officers

- Facility managers

- Maintenance supervisors

- Fire wardens

- HSE professionals responsible for fire readiness

Conclusion

A fire hydrant system is only effective when it works automatically, reliably, and under real fire conditions. Most hydrant failures occur due to poor maintenance, incorrect installation, or lack of regular testing. Understanding how the system operates and where it commonly fails is essential for preventing fire escalation.

Fire safety is not about having equipment installed. It is about ensuring the system works when it is needed most.

Components of a Fire Hydrant System: Detailed Explanation of Parts and Functions

How to Operate a Fire Hydrant: Step-by-Step Procedure, Safety Rules, and Technical Guidelines

Fire Pump Room Layout and Requirements

Fire Hydrant Testing Procedure