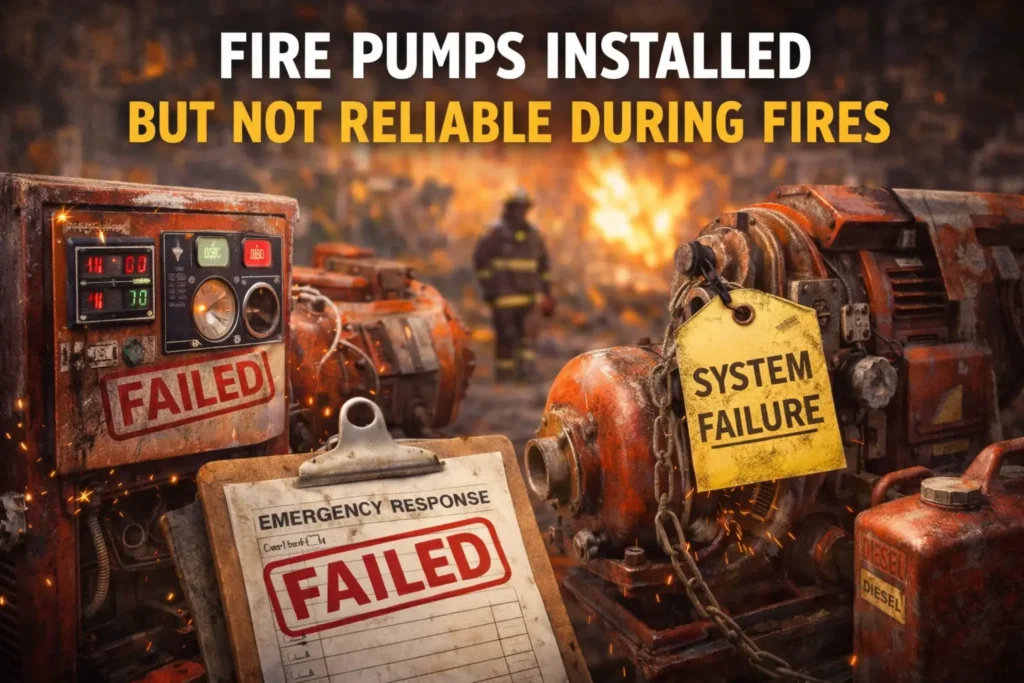

Fire Pumps Installed but Not Reliable During Fires

In many factories, warehouses, and commercial buildings, the fire pump room looks impressive.

There is a diesel pump.

An electric pump.

A jockey pump.

Control panels.

Pressure gauges.

Big red pipelines.

Everything appears perfect.

Management proudly says, “We have a complete fire pump system.”

But during an actual fire emergency, the harsh truth comes out.

The pump does not start.

Pressure drops suddenly.

Water supply fails.

The motor trips.

Or the pump runs but delivers almost no flow.

This situation is more common than most people think.

A fire pump that is installed but not reliable is worse than having no pump at all, because it creates a false sense of safety.

This article explains why fire pumps fail during real fires and how industries can ensure true reliability.

What Is the Real Purpose of a Fire Pump?

A fire pump has one job only.

Deliver water at required pressure and flow instantly during a fire.

It must:

• Start automatically

• Maintain pressure

• Run continuously

• Supply adequate water

• Work without human intervention

If any of these fail, the entire firefighting system collapses.

During a fire, even a 60 second delay can double the fire size.

There is no time for repairs or troubleshooting.

The pump must work the first time, every time.

The Hidden Problem in Most Industries

Many companies treat fire pumps like “install and forget” equipment.

After installation:

• No one tests them

• No one inspects them

• No one takes responsibility

Months or years pass without operation.

Mechanical systems that are never used will fail.

It is guaranteed.

Pumps are machines. Machines need movement, testing, and maintenance.

Without it, they silently degrade.

Common Reasons Fire Pumps Fail During Fires

Let us look at the most frequent real world failures observed in industrial sites.

1. Pump Does Not Start Automatically

This is the most dangerous situation.

Pressure drops.

System demands water.

Pump should start.

Nothing happens.

Reasons include:

• Auto mode turned OFF

• Control panel fault

• Battery dead (diesel pump)

• Sensor failure

• Wiring issues

• Manual isolation switch left open

If the pump fails to start, hydrants and sprinklers remain dry.

2. Diesel Engine Problems

Diesel pumps are widely used because they work during power failure.

But many diesel pumps fail due to simple neglect.

Common issues:

• Empty diesel tank

• Contaminated fuel

• Dead battery

• Starter motor failure

• Cooling system problems

• No weekly running

Diesel engines must be started regularly.

If they sit idle for months, they will not start during emergencies.

3. Electrical Pump Trips Immediately

Electric fire pumps often trip when started.

Causes:

• Overload settings incorrect

• Motor insulation damage

• Loose wiring

• Low voltage

• Poor maintenance

• Control panel faults

During emergencies, the pump may start and stop repeatedly.

This results in pressure loss and ineffective firefighting.

4. Low Discharge Pressure

Sometimes the pump runs but water pressure is too weak.

This is equally dangerous.

Reasons:

• Worn impeller

• Air trapped in suction

• Clogged suction strainer

• Leaking pipelines

• Incorrect pump sizing

• Partially closed valves

Low pressure means:

• Short hose throw

• No sprinkler coverage

• Inability to reach fire source

5. Pump Room Poorly Maintained

Many pump rooms are treated like storage areas.

You may find:

• Dust and dirt

• Oil leakage

• Rust

• Spare parts piled around

• No lighting

• No ventilation

Such environments lead to mechanical failure.

Fire pumps require clean, accessible, well maintained rooms.

6. No Water in Tank

This sounds unbelievable but happens frequently.

During inspection:

Tank looks fine.

During fire:

Tank empty.

Reasons:

• Used for domestic or process water

• No level monitoring

• Leakage

• No refill system

• Operator negligence

Without water, even the best pump is useless.

7. Jockey Pump Malfunction

The jockey pump maintains system pressure.

If it fails:

• Main pump starts frequently

• System pressure fluctuates

• Mechanical wear increases

Eventually the main pump becomes unreliable.

Small equipment failures often create bigger failures.

Why Fire Pump Failures Are Dangerous

Fire grows exponentially.

In just a few minutes:

Small flame becomes uncontrollable.

If the pump fails:

• Hydrants useless

• Sprinklers ineffective

• Fire spreads rapidly

• Fire brigade arrival delayed

• Damage multiplies

Financial losses can reach crores within minutes.

More importantly, lives are at risk.

Early Warning Signs of Unreliable Fire Pumps

Safety officers should watch for:

• Pump never tested

• No maintenance records

• Diesel smell or leakage

• Rusted valves

• Pressure gauge always zero

• Batteries weak

• Alarm faults ignored

• Pump room locked and dusty

These signs mean the pump is not dependable.

How to Make Fire Pumps Truly Reliable

Now let us talk about solutions.

Reliability is achieved through routine testing and preventive maintenance.

Weekly Actions

• Start diesel pump for 10 to 15 minutes

• Run electric pump

• Check battery condition

• Verify pressure readings

• Inspect fuel level

Monthly Actions

• Test automatic start

• Check control panel alarms

• Inspect valves

• Clean suction strainers

• Verify jockey pump operation

• Check for leakage

Quarterly Actions

• Flow test pump performance

• Measure discharge pressure

• Check electrical connections

• Lubricate moving parts

• Clean pump room

Annual Actions

• Full performance test

• Engine servicing

• Replace worn components

• Calibrate sensors

• Third party audit

Importance of Documentation

Every test must be recorded.

Maintain:

• Weekly test log

• Maintenance checklist

• Fuel record

• Fault report

• Repair history

Documentation proves system readiness and helps during audits.

Without records, there is no proof of reliability.

Real Incident Example

In one manufacturing plant, a conveyor belt caught fire.

The sprinkler system activated.

But the fire pump failed to start.

Diesel tank was empty.

The pump had not been tested for six months.

By the time external firefighters arrived, the entire production area was damaged.

Investigation concluded:

Installation was perfect.

Maintenance was zero.

Losses exceeded several crores.

All because of one neglected pump.

Role of Safety Officers

A fire pump needs ownership.

Assign a responsible person who:

• Conducts weekly tests

• Maintains logs

• Reports faults

• Coordinates repairs

• Trains operators

If everyone is responsible, no one is responsible.

Ownership ensures reliability.

External Reference

For official guidance on fire pump inspection, testing, and maintenance practices, refer to the NFPA standards and fire protection education resources published by the National Fire Protection Association, which provide globally recognized recommendations for maintaining reliable fire pump systems in industrial facilities.

Frequently Asked Questions

1. How often should fire pumps be tested?

At least weekly for running tests and annually for full performance tests.

2. Is diesel pump better than electric pump?

Both are important. Diesel works during power failure, electric is easier to maintain.

3. Can a pump fail even if new?

Yes. Without testing, even new pumps can fail.

4. Who should operate fire pumps?

Trained maintenance or safety personnel only.

5. Why is automatic mode important?

Because during emergencies there is no time for manual start.

Conclusion

Installing a fire pump is only the first step.

Reliability comes from testing, maintenance, and responsibility.

A pump that looks powerful but fails during a fire is not protection.

It is false confidence.

Weekly testing, proper maintenance, and trained operators transform fire pumps from decorative equipment into true lifesaving systems.

Remember this simple rule.

If you have not tested your fire pump recently, you cannot trust it.

Fire Hydrant Systems That Look Ready but Fail

Fire Hydrant System Explained, How It Works, Why It Fails, and How to Keep It Fire Ready

Components of a Fire Hydrant System, How Each Part Fails or Saves a Fire Response

How to Operate a Fire Hydrant Safely During an Emergency

Fire Pump Room Layout and Requirements Explained Simply and Practically