Heat Sources in Industrial Fires, Where Ignition Really Starts and How to Stop It

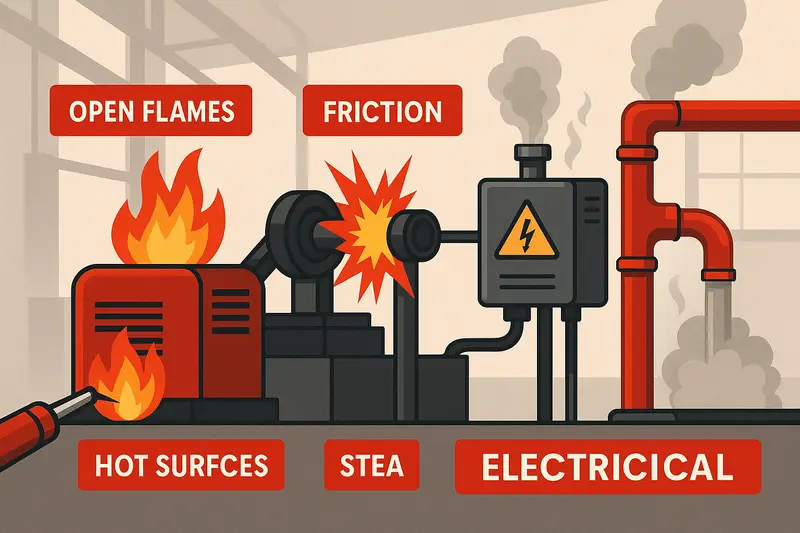

In industrial fires, heat is rarely accidental. Investigations consistently show that ignition occurs because heat sources were known, present, and poorly controlled. Whether the fire starts from electrical overheating, friction, hot work, or chemical reactions, heat is almost always the trigger that completes the fire triangle.

According to HSE fire and explosion guidance, uncontrolled heat sources such as hot work, friction, electrical faults, and overheating equipment can act as ignition sources in industrial fires.

This guide explains industrial heat sources from a real world fire prevention perspective, focusing on how heat builds up, where controls fail, and what actions actually prevent ignition in factories, plants, warehouses, and processing facilities.

Why Heat Is the Primary Ignition Trigger in Industry

Fuel and oxygen are present in almost every industrial environment. What turns a normal operation into a fire is uncontrolled heat.

Heat becomes dangerous when:

- Temperatures exceed safe operating limits

- Heat is transferred to nearby combustibles

- Sparks or hot particles reach flammable atmospheres

- Heat accumulates unnoticed over time

Preventing industrial fires starts with controlling heat before ignition temperature is reached.

Where Heat Risks Are Highest in Industrial Plants

High heat risk is common in:

- Manufacturing and fabrication plants

- Refineries and chemical facilities

- Power generation units

- Warehouses with machinery and heaters

- Paint shops, curing ovens, and dryers

- Maintenance and hot work areas

In these environments, heat control must be systematic, not reactive.

Open Flames and Hot Work, The Leading Ignition Source

Welding, Cutting, and Grinding

Hot work activities generate extremely high temperatures and sparks that can travel long distances.

Common ignition scenarios:

- Sparks falling through floor openings

- Smoldering fires inside insulation or wall cavities

- Ignition of vapors not detected before work

Most hot work fires occur after the job is completed, not during the task.

Why controls fail

- No proper hot work permit

- Fire watch ends too early

- Poor housekeeping around the work area

Electrical Heat and Arcing, The Hidden Fire Starter

Electrical systems generate heat continuously. When defects develop, heat rises silently.

Typical failure points:

- Loose panel terminations

- Overloaded cables

- Undersized conductors

- Dust accumulation in panels

- Blocked ventilation

Electrical arcing produces extreme temperatures and molten metal, often igniting insulation inside enclosures where fires remain hidden until advanced.

Most electrical fires are maintenance failures, not sudden faults.

Hot Surfaces and Radiant Heat Exposure

Industrial equipment often operates at temperatures high enough to ignite nearby materials.

High risk surfaces include:

- Furnaces and ovens

- Steam and hot oil pipelines

- Exhaust systems

- Motors, bearings, and gearboxes

Common ignition mistakes:

- Storage placed against hot equipment

- Missing insulation or damaged lagging

- No temperature monitoring on critical assets

If a surface is hot enough to discolor paint or insulation, it is already a fire risk.

Frictional Heat from Moving Equipment

Friction is a major but underestimated heat source.

Typical ignition points:

- Seized or misaligned bearings

- Conveyor belt slip

- Overloaded rollers

- Brake systems on industrial vehicles

Frictional heat can ignite:

- Rubber conveyor belts

- Dust layers

- Packaging materials

These fires usually develop slowly and escalate rapidly once ignition occurs.

Chemical Heat and Spontaneous Ignition

Some industrial fires start without any spark or flame.

Exothermic Reactions

Chemical reactions can release large amounts of heat if not properly controlled.

Failure scenarios:

- Cooling systems not functioning

- Incorrect mixing ratios

- Process upset conditions

Spontaneous Combustion

Materials such as oily rags, coal, biomass, and some metal powders can self heat over time.

These fires often occur:

- In storage areas

- During shutdown periods

- Overnight or on weekends

Heat Transfer, How Fire Spreads Beyond the Source

Understanding heat movement helps predict fire spread.

Conduction

Heat travels through metal structures, igniting materials far from the source.

Convection

Hot gases rise, spreading fire into ceilings, ducts, and upper floors.

Radiation

Intense heat ignites materials without direct contact.

Poor layout and lack of shielding allow small fires to become major incidents.

Practical Controls That Actually Prevent Heat Related Fires

Engineering Controls

- Insulation of hot surfaces

- Temperature sensors on bearings and motors

- Thermal imaging of electrical panels

- Interlocks and automatic shutdowns

- Proper ventilation of heat producing equipment

Administrative Controls

- Hot work permit systems

- Defined fire watch duration after hot work

- Preventive maintenance schedules

- Safe storage rules near heat sources

- Clear shutdown procedures during abnormalities

Safe Work Practices

- No combustible storage near hot equipment

- Never bypass temperature alarms

- Immediate reporting of overheating or unusual smells

- Proper disposal of oily rags in metal containers

- Training workers to recognize early heat warning signs

Inspection Focus Areas for Heat Hazards

Effective inspections check for:

- Overheated bearings or motors

- Discolored cables or panels

- Missing insulation

- Combustibles near hot surfaces

- Uncontrolled hot work activities

- Poor housekeeping around machinery

Inspections that only review paperwork do not prevent fires.

Common Heat Related Failures Seen After Industrial Fires

- Hot work done without permits

- Maintenance postponed to avoid downtime

- Temperature alarms disabled

- Temporary heaters used permanently

- Storage encroaching into equipment clearances

These failures are repeatedly identified in fire investigation reports.

Who Should Use This Guide

This guide is intended for:

- Safety officers

- Maintenance managers

- Production supervisors

- Plant engineers

- Employers responsible for industrial fire prevention

Conclusion

Heat is present in almost every industrial operation. Fires occur not because heat exists, but because heat is allowed to exceed safe limits near fuel and oxygen. By identifying high risk heat sources, understanding how heat transfers, enforcing strong hot work controls, and maintaining equipment properly, industries can prevent most ignition events.

Fire prevention does not start with extinguishers. It starts with controlling heat long before ignition occurs.

Fire Triangle Explained: Definition, Elements, Examples and Importance

Electrical Fire Safety: Causes, Controls, and Prevention Measures