DCP Fire Extinguisher, Why It Works So Fast and Why It Often Fails After That

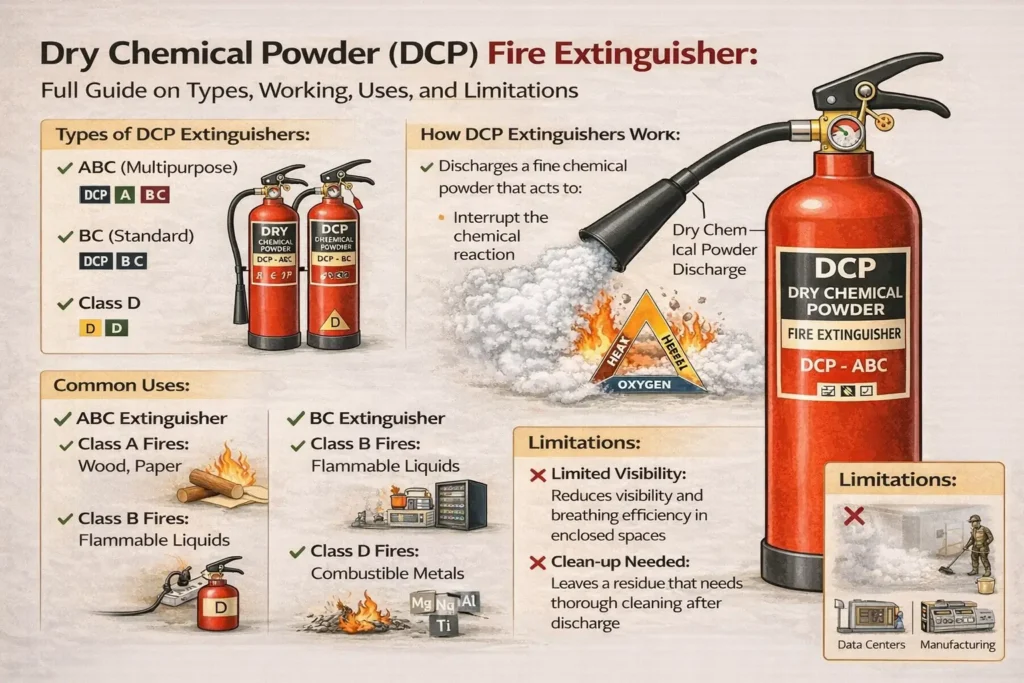

Dry Chemical Powder, commonly known as DCP, is one of the most widely installed fire extinguishers in the world. It is often called a “multi-purpose” or “universal” extinguisher because it can knock down flames on many different types of fires. Because of this reputation, DCP is frequently chosen as the default solution for homes, vehicles, factories, fuel stations, and industrial sites.

However, fire investigations show a consistent pattern. DCP extinguishers stop flames quickly, but fires often re-ignite if people do not understand what DCP can and cannot do.

According to HSE fire and explosion guidance, dry chemical powder extinguishers interrupt the chemical reaction of fire and are suitable for multiple fire classes, but they have visibility and residue limitations.

This guide explains DCP fire extinguishers from a real-world fire response and safety perspective, focusing on why they work so fast, where they are most effective, and where people make costly mistakes.

What a DCP Extinguisher Actually Does

Unlike water or foam, DCP does not rely mainly on cooling or oxygen removal.

A DCP extinguisher works by:

- Interrupting the chemical chain reaction inside the flame

- Collapsing the flame front almost instantly

- Smothering the burning surface with fine powder

This is why DCP is extremely effective on fast-growing liquid and gas fires, where rapid flame knockdown is critical.

Why DCP Knocks Down Flames So Quickly

In a burning flame, highly reactive particles keep the fire alive. When dry chemical powder enters the flame zone:

- These reactive particles are neutralized

- The chemical reaction cannot continue

- Flames collapse almost immediately

This speed is the biggest advantage of DCP.

Fires Where DCP Is the Best Choice

DCP extinguishers perform very well when:

- Flames are spreading rapidly

- Fuel vapours are present

- Electrical equipment is involved

- Outdoor conditions make CO₂ ineffective

Typical examples include:

- Fuel station and vehicle fires

- Flammable liquid spills

- Gas fires after isolation

- Electrical panels and machinery

- Workshops and industrial equipment

In these situations, DCP often stops fire faster than water, foam, or CO₂.

Why DCP Is So Common in Industry

DCP is widely used because it:

- Works on multiple fire types

- Is not affected much by wind

- Is safe on live electrical equipment

- Has long storage life

- Is relatively low cost

For mixed-risk areas, DCP is often the first extinguisher available.

The Biggest Weakness of DCP That People Ignore

DCP does not cool fuel effectively.

This means:

- Hot surfaces can remain above ignition temperature

- Vapours can continue forming

- Fire may re-ignite once powder settles

Many fires that appear “extinguished” with DCP restart minutes later.

Fires Where DCP Performs Poorly

Deep-Seated Solid Fires

On wood, fabric, paper, or furniture:

- Flames may stop

- Smouldering continues underneath

- Fire can re-ignite later

Water or foam is usually required after DCP to cool the material.

Cooking Oil Fires

DCP is not designed for hot oil:

- Powder does not cool the oil

- Splashing and flare-ups can occur

- Wet chemical extinguishers are safer

Sensitive Electronic Areas

Although DCP is non-conductive:

- Powder enters equipment

- Fans and circuits are contaminated

- Corrosion and failure may occur later

This is why data centers prefer CO₂ or clean agents.

Common DCP Mistakes Seen During Real Fires

Fire audits and investigations frequently find:

- DCP used without removing the heat source

- Users walking away immediately after flame knockdown

- No monitoring for re-ignition

- Powder discharged blindly into equipment

- Excessive use reducing visibility and escape safety

Most failures come from overconfidence in DCP.

How to Use DCP Safely and Effectively

Good practice when using DCP includes:

- Aim at the base of the fire, not the flames

- Use short, controlled bursts if possible

- Sweep to cover the burning surface completely

- Watch carefully for re-ignition

- If safe, remove or isolate the heat source

- Follow up with cooling if required

Extinguishing flames is only the first step.

Gas and Electrical Fires, A Special Note

For gas fires:

- Do not extinguish flames unless the gas supply can be shut off

- A burning gas jet is safer than an unignited gas cloud

For electrical fires:

- DCP is effective

- Expect heavy cleanup afterward

- Restore equipment only after inspection

Why Visibility Becomes a Problem With DCP

When discharged:

- Fine powder fills the air

- Visibility drops sharply

- People may lose orientation

- Evacuation routes become harder to see

This is a major concern in confined spaces and corridors.

Maintenance Problems That Reduce DCP Performance

A DCP extinguisher may fail if:

- Powder has compacted inside

- Pressure has leaked out

- Hose or nozzle is blocked

- Cylinder is corroded

Routine inspection and periodic shaking or servicing are essential.

Where DCP Extinguishers Are Essential

DCP extinguishers are strongly recommended in:

- Fuel stations and vehicle areas

- Chemical and petrochemical plants

- Workshops and fabrication units

- Warehouses with mixed hazards

- Construction and mining equipment

- Outdoor industrial installations

In these locations, fast flame knockdown is critical.

Who Should Use This Guide

This guide is intended for:

- Safety officers and fire wardens

- Industrial supervisors

- Vehicle and equipment operators

- Facility and maintenance managers

- Emergency response team members

Conclusion

DCP fire extinguishers are powerful tools that stop flames faster than most other portable extinguishers. Their ability to interrupt the chemical chain reaction makes them ideal for flammable liquids, gases, and electrical fires. At the same time, they provide little cooling and create heavy residue, which means re-ignition and equipment damage are real risks if users do not understand their limits.

Effective fire safety is not about choosing the extinguisher that works fastest. It is about choosing the extinguisher that works correctly for the fire and managing what happens after the flames go out.

Types of Fire Extinguishers: Complete Guide to Uses, Classes, Color Codes and Selection

Water Extinguisher: Uses and Limitations

Foam Fire Extinguishers and AFFF Explained: Working, Types, Uses, and Limitations

CO₂ Fire Extinguisher: Working Principle, Uses, Limitations, and Industrial Applications