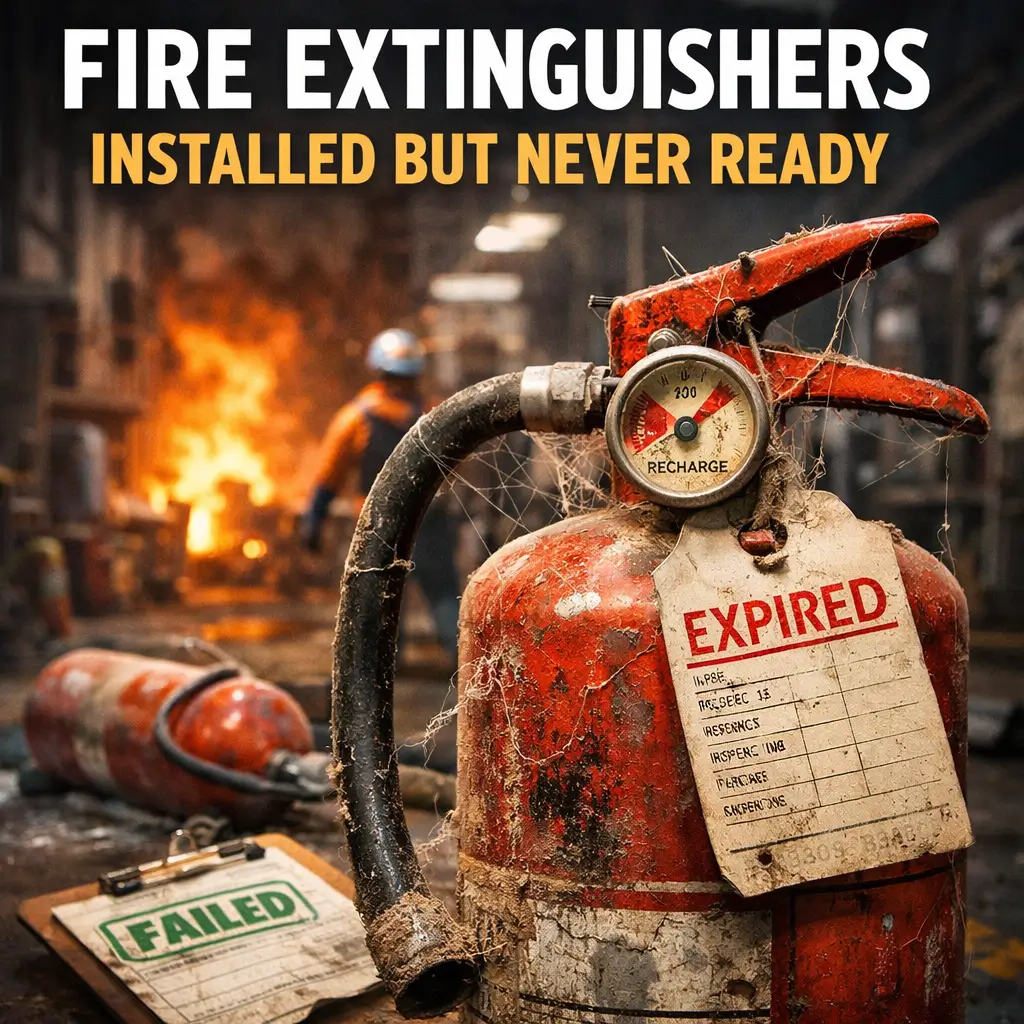

Fire Extinguishers Installed but Never Ready

Fire safety authorities consistently highlight that many failures during emergencies are caused by poor awareness, incorrect equipment selection, and lack of routine inspection rather than the absence of fire protection systems. Guidance published by the National Fire Protection Association (NFPA) explains how proper fire extinguisher selection, maintenance, and user training play a critical role in preventing fire escalation. Practical fire safety education and prevention guidelines can be referred to through NFPA’s official fire safety education resources, which are widely followed across industries and residential environments.

In many Indian workplaces, fire extinguishers are installed on walls, pillars, and near exits exactly as required by safety rules. On paper, everything looks compliant. During audits, the boxes are ticked. During inspections, the extinguishers are counted.

But when a real fire emergency occurs, a harsh reality is often exposed: the fire extinguisher is present but not usable.

This is one of the most dangerous and overlooked fire safety failures in Indian industries. A fire extinguisher that is installed but not ready creates a false sense of safety, putting lives, assets, and operations at serious risk.

What Does “Installed but Never Ready” Mean?

A fire extinguisher is considered “not ready” when it:

- Cannot be operated immediately

- Fails to discharge properly

- Is unsafe to use

- Is ineffective for the fire involved

In such cases, the extinguisher becomes nothing more than a wall decoration.

Common Reasons Fire Extinguishers Are Not Ready

Expired or Overdue for Refilling

One of the most common issues is expired extinguishers.

Typical problems include:

- Refilling date crossed

- Hydrostatic test overdue

- Service tag missing or outdated

Many extinguishers remain unrefilled for years after installation.

Loss of Pressure

Pressure loss is especially common in:

- Stored pressure extinguishers

- CO₂ extinguishers with slow leakage

Signs include:

- Gauge needle in red zone

- Reduced discharge force

- Partial discharge only

During emergencies, users press the handle only to find weak or no output.

Blocked or Damaged Nozzles

Extinguishers installed in dusty or industrial environments often suffer from:

- Clogged discharge hoses

- Insect nests inside nozzles

- Paint overspray blocking outlets

These issues are rarely visible without inspection.

Missing Safety Pins or Broken Seals

In some workplaces:

- Safety pins are removed for “demonstration” and never replaced

- Seals are broken by curious workers

- Extinguishers are tampered with

This makes the extinguisher unreliable and unsafe.

Corrosion and Physical Damage

Industrial conditions accelerate corrosion due to:

- Humidity

- Chemical exposure

- Outdoor installation

Damaged cylinders can:

- Leak pressure

- Fail during discharge

- Become unsafe to handle

Improper Mounting and Accessibility

Many extinguishers are:

- Installed too high or too low

- Blocked by materials

- Locked inside cabinets without keys

In emergencies, seconds matter. Delayed access makes extinguishers useless.

Why This Problem Is So Common in Indian Workplaces

Fire Safety Treated as a One-Time Activity

Extinguishers are often installed:

- During project completion

- Before safety audits

- For regulatory compliance

After installation, ongoing readiness is ignored.

No Ownership or Responsibility

In many organizations:

- No one is clearly responsible for extinguisher readiness

- Maintenance is outsourced without monitoring

- Safety checks are done only on paper

Without accountability, extinguishers degrade silently.

Inadequate Inspection Practices

Monthly inspections are either:

- Not done

- Done without technical understanding

- Recorded without physical checks

A quick glance is not enough to verify readiness.

Lack of Training and Awareness

Workers often:

- Do not know how to inspect extinguishers

- Cannot identify pressure loss

- Are unaware of refilling cycles

Without training, problems remain unnoticed.

Real Incident Patterns Observed in Fire Investigations

Fire investigation reports frequently reveal:

- Extinguishers empty due to slow leakage

- Discharge hoses blocked with dust

- Expired extinguishers failing to operate

- Workers unable to activate extinguishers

In many cases, fires that could have been controlled in seconds escalated into major incidents.

Legal and Safety Consequences

An extinguisher installed but not ready can lead to:

- Violation of fire safety laws

- Insurance claim rejection

- Penalties from authorities

- Legal liability for management

Courts consider non-functional safety equipment as negligence.

How to Ensure Fire Extinguishers Are Always Ready

Implement Monthly Physical Inspections

Every extinguisher should be checked for:

- Pressure gauge condition

- Seal and pin integrity

- Hose and nozzle cleanliness

- Mounting condition

Inspections must be physical, not just checklist-based.

Follow Refilling and Testing Schedules

Ensure:

- Refilling is done as per manufacturer recommendations

- Hydrostatic testing is completed on time

- Records are maintained properly

Never ignore service due dates.

Assign Clear Responsibility

Each area should have:

- A designated safety in-charge

- Clear inspection ownership

- Escalation procedure for defects

Responsibility prevents neglect.

Conduct Practical Training

Training should include:

- How to identify unready extinguishers

- Hands-on operation practice

- Basic inspection awareness

A trained worker is the first line of defense.

Frequently Asked Questions (FAQs)

Can an expired fire extinguisher still work?

Sometimes it may discharge, but reliability is not guaranteed. Using expired equipment is unsafe and unacceptable.

How often should fire extinguishers be inspected?

Visual inspections should be done monthly, and servicing should follow manufacturer and regulatory guidelines.

Is pressure gauge alone enough to confirm readiness?

No. Hose condition, seal integrity, and physical damage must also be checked.

Who is responsible if an extinguisher fails during a fire?

The employer and safety management are legally responsible for maintaining ready-to-use fire protection equipment.

Are old extinguishers dangerous?

Yes. Corroded or damaged extinguishers can rupture or malfunction during use.

Conclusion

Fire extinguishers save lives only when they are ready at the moment of need. In Indian industries, the problem is rarely the absence of extinguishers, but their poor readiness and neglected maintenance.

Fire safety is not about installation. It is about continuous reliability. An extinguisher that fails during an emergency is worse than having none at all.

Ensuring readiness is a simple but powerful step toward preventing small fires from becoming major disasters.

Types of Fire Extinguishers Explained, How to Select the Right One for Real Workplace Fires

Water Extinguisher, When It Works, When It Fails, and How People Misuse It

Foam Fire Extinguishers, When They Are the Best Choice and When They Are Dangerous

CO₂ Fire Extinguisher, Where It Works Perfectly and Where It Becomes Dangerous

DCP Fire Extinguisher, Why It Works So Fast and Why It Often Fails After That